Battery Test Chambers

AES Fully Integrated Battery Testing Solutions

What Is a Battery Test Chamber?

Battery test chambers simulate the most intense real-world conditions your cells are likely to encounter, including extreme temperatures and humidity. You can assess their effectiveness and reliability by charging and discharging them in a controlled workspace.

We're adaptable.

WE’RE LEAN.

WE'RE INTEGRATORS.

5000+

Active Battery Test Chambers

200,000+

Active channels deployed in our ATP systems

up to 1200 Amps

Our ATP solutions can be accommodate less than 1 amp up to 1200 amps continuous or pulse

Find the Battery Chamber That’s Right for You

AES fills a significant industry gap by providing patented integration of chambers and battery testing equipment, offering a single-source solution. This streamlines operations, saving time and money for customers. With extensive experience and expertise, AES ensures efficient installation processes, minimizing costly delays and mistakes. With hundreds of thousands of active battery test channels to date, AES has established a proven track record in the field. Choose AES for your chamber and fixture needs, experiencing convenience, reliability, and optimized productivity.

Seamless connection to your cycler

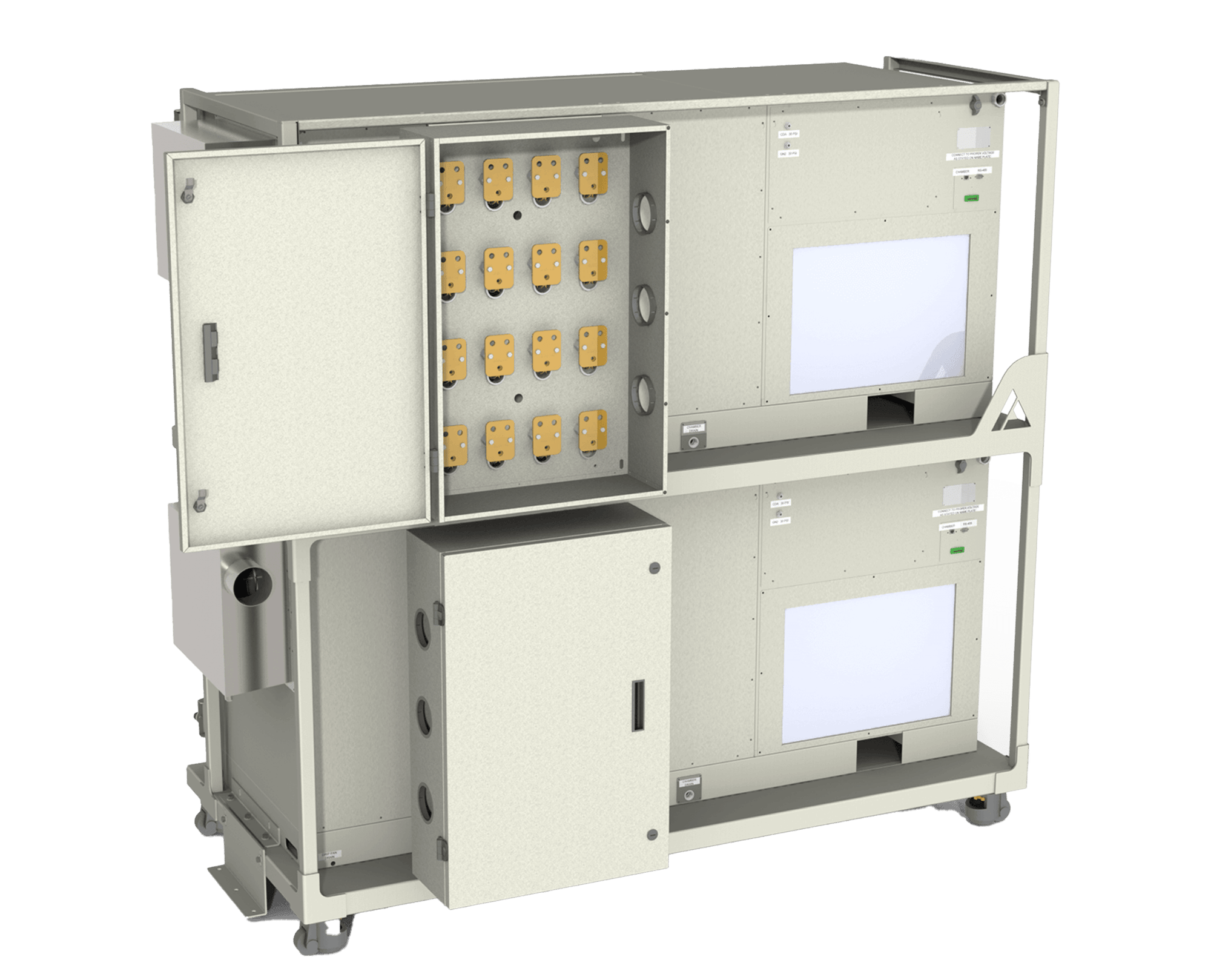

ATP/Cycler Interface Panel

Our cycler interface panel, situated at the rear of the chamber, features isolated terminal posts for connecting current-carrying wires from the cycler and isolated turret-style connectors that facilitate easy interfacing with cycler sense wires. This offers a secure location for connections and ensures safety and functionality for direct communication about the health of your cell.

SC-512-SAFE: ATP Interface Panel

BENCHTOP BATTERY TEST CHAMBERS

SC/SCH SAFE SERIES

The SC (temperature-only) and SCH (temperature and humidity) Series feature the most powerful benchtop chambers in the world. These chambers enable you to precisely control the environmental conditions within the chamber’s workspace. These chambers are stackable and engineered to work seamlessly with battery testing fixtures.

SC/SCH-508-SAFE

SC/SCH-512-SAFE

Specs at a Glance

- Temp Range: -37°C - 180°C

- Humidity Range: 10%-95% RH(SCH only)

- Pulldown Rate: 5°C/min.

- Working Volume: 8.64 cubic feet(SC/SCH-508), 12.94 cubic feet(SC/SCH-512)

- Available Models: SC-508-SAFE, SCH-508-SAFE, SC-512-SAFE, SCH-512-SAFE

AESONE CONNECT®

SC and SCH Series chambers come standard with AESONE CONNECT®, enabling you to remotely monitor your chamber from a desktop, laptop, or tablet from any location.

AES SAFE

Battery Test Chambers included with battery safety testing features equipped to handle up to hazard level 7:

- Emergency Stop Button

- High/Low Temperature Limit

- Rapid Temperature Change

- Audible and Visual Alarm

- Temperature Limited Sheath Heaters

- Enhanced Remote Door Lock

- Burst Disk/Low Flow Vent

- Safety Purge

- Product Sensors

- Reinforced Inner Wrap

- Chamber Alarm Input

- Chamber Alarm Output

BENCHTOP BATTERY TEST CHAMBERS

SD/BHD SAFE Series

The SD (temperature-only) and BHD (temperature and humidity) Series give you precise control over conditions in your chamber’s workspace to enable effective battery testing. They are stackable, optimizing your footprint.

SD/BHD-508-SAFE

SD-501-SAFE

SD-501-3RS

Specs at a Glance

- Temp Range: -37°C - 180°C

- Humidity Range: 10%-95% RH(BHD only)

- Rise Rate: 2.8°C/min.(SD-501 only)

- Pulldown Rates:

3°C/min.(SD-501)

1.24°C/min.(SD-508)

4°C/min.(BHD-508) - Working Volume: 8.00 cubic feet (SD/BHD 508), 1.00 cubic feet (SD-501)

- Available Models: SD-501-SAFE, SD-508-SAFE, BHD-508-SAFE

AESONE CONNECT®

SD and BHD Series chambers come standard with AESONE CONNECT®, enabling you to remotely monitor your chamber from a desktop, laptop, or tablet from any location.

AES SAFE

Battery Test Chambers included with battery safety features equipped to handle up to hazard level 7:

- Emergency Stop Button

- High/Low Temperature Limit

- Rapid Temperature Change

- Audible and Visual Alarm

- Temperature Limited Sheath Heaters

- Enhanced Remote Door Lock

- Burst Disk/Low Flow Vent

- Safety Purge

- Product Sensors

- Reinforced Inner Wrap

- Chamber Alarm Input

- Chamber Alarm Output

Building a Battery Testing Lab or Planning an Expansion?

AES has years of experience working with companies across industries, designing high-powered battery labs. We provide installation and guidance on power requirements, necessary spacing between chambers to account for performance and employee movement, HVAC systems, safety measures, and education on proper use. We work with your chosen testing chamber manufacturer to provide the best test solution for the optimal test setup. We can help you plan for now and the future.

TALK TO A BATTERY TESTING SPECIALIST| Severity Level | Description | Severity Classification & Effects Criteria |

|---|---|---|

| 0 | No Effect | No effect. No loss of functionality. |

| 1 | Reversible Loss of Function | No defect; no leakage; no venting, fire, or flame; no rupture; no explosion; no exothermic reaction or thermal runaway. Cell reversibly damaged. Repair of protection device needed. |

| 2 | Irreversible Defect/Damage | No leakage; no venting, fire, or flame; no rupture; no explosion; no exothermic reaction or thermal runaway. Cell irreversibly damaged. Repair needed. |

| 3 | Leakage Δ mass <50% |

No venting, fire, or flame; no rupture; no explosion. Weight loss <50% of electrolyte weight (electrolyte = solvent + salt). |

| 4 | Venting Δ mass >=50% |

No fire or flame; no rupture; no explosion. Weight loss ≥50% of electrolyte weight (electrolyte = solvent + salt). |

| 5 | Fire or Flame | No rupture; no explosion (i.e., no flying parts). |

| 6 | Rupture | No explosion, but flying parts of the active mass. |

| 7 | Explosion | Explosion (i.e., disintegration of the cell) |

*Gas Sensors and Additional Safety Features Available