Electric Vehicle Battery Testing

The electric vehicle (EV) industry continues to innovate, with cars that can drive longer and further per battery charge than ever before. Associated Environmental Systems (AES) has created a suite of battery testing solutions to address the needs of a constantly evolving EV landscape.

What Is EV Battery Testing?

Your electric vehicle (EV) batteries will encounter extreme conditions, high and low altitudes, hills and highways, and diverse climates as passengers drive around the world. Will they surpass the challenges of the road? Rigorously testing your batteries to ensure performance, safety, and reliability is crucial to driving innovation in the EV industry. AES is here to help you do that.

Why AES?

Setting the Standard in the EV Battery Test Chamber Industry

Patented for a system for the high-density testing of batteries within an environmental test chamber, AES offers battery testing solutions that are equipped to grow with you and your battery testing needs as the EV industry changes.

Adaptable

SAFE

Efficient

High-Amperage Battery Testing for Cylindrical, Pouch, and Prismatic Cells

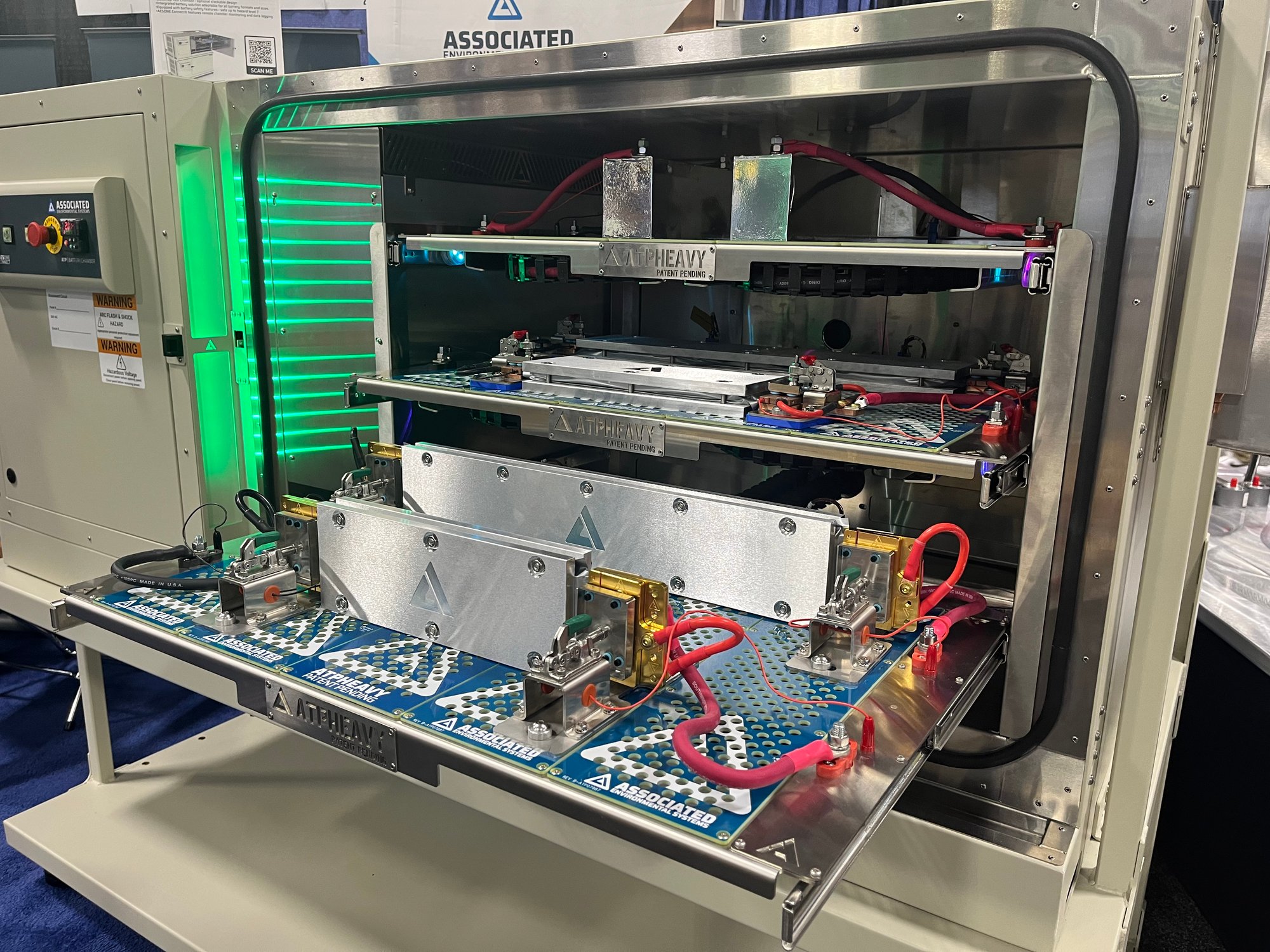

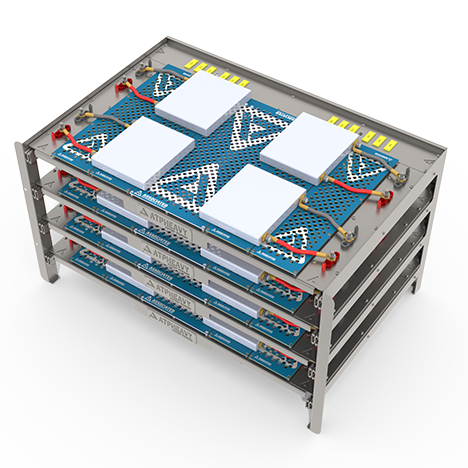

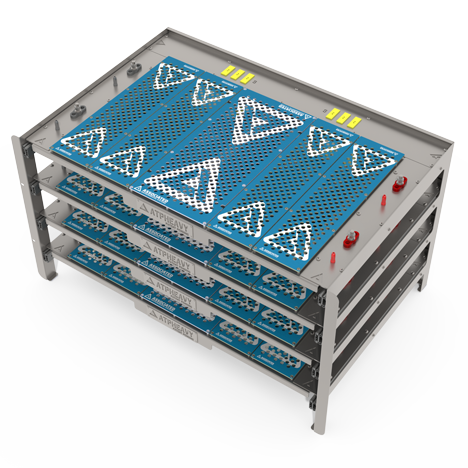

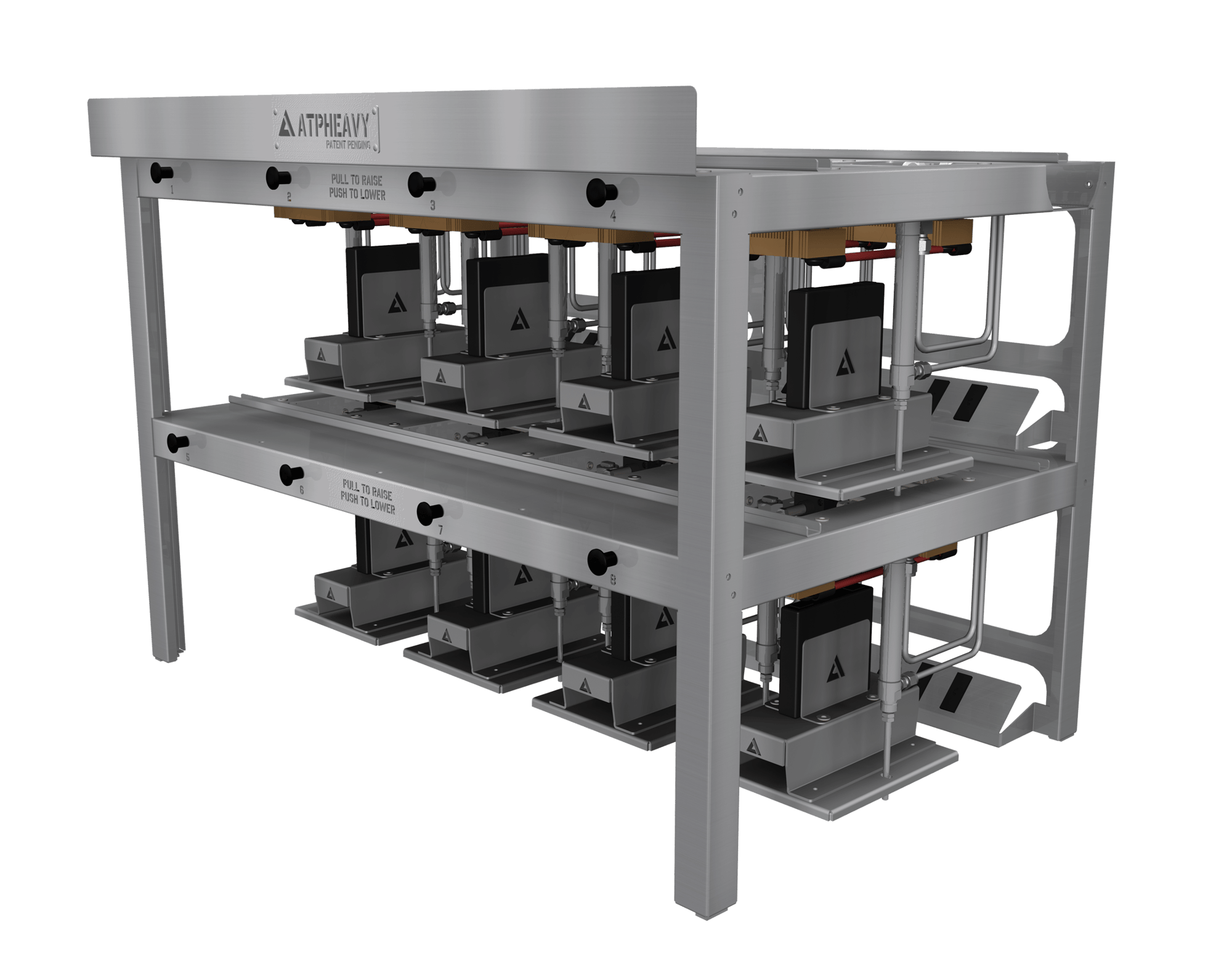

ATPHEAVY® ADAPTABLE

Patent-pending ATPHEAVY ADAPTABLE® comes with sliding shelves and can be adjusted to accommodate different setups and battery formats. It’s compatible with the SC-512-SAFE.

Featuring: Vertical Pouch

Featuring: Pouch or Prismatic

Featuring: Prismatic

Featuring: Horizontal Pouch

Specs at a Glance

- Application: High Current

- Channels: 6-16 Channels

- Cell Format: Cylindrical, Pouch, and Prismatic

- Maximum Current: 500 Amps

- Cable Management: Cable Chain

Adaptable Testing

Universal terminals on both sides provide an adaptable and agile solution for battery testing. For instance, you can replace a jumper cable with a pouch cell clip modular component, allowing for flexible reconfiguration and repurposing.

Cycler Connection

Our cycler interface panel, situated at the rear of the chamber, features isolated terminal posts for connecting current-carrying wires from the cycler and isolated turret-style connectors that facilitate easy interfacing with cycler sense wires. This offers a secure location for connections and ensures safety and functionality for direct communication about the health of your cell.

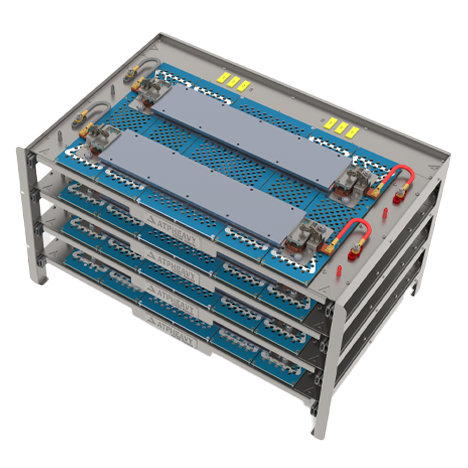

High-Amperage Battery Testing for Cylindrical and Prismatic Cells

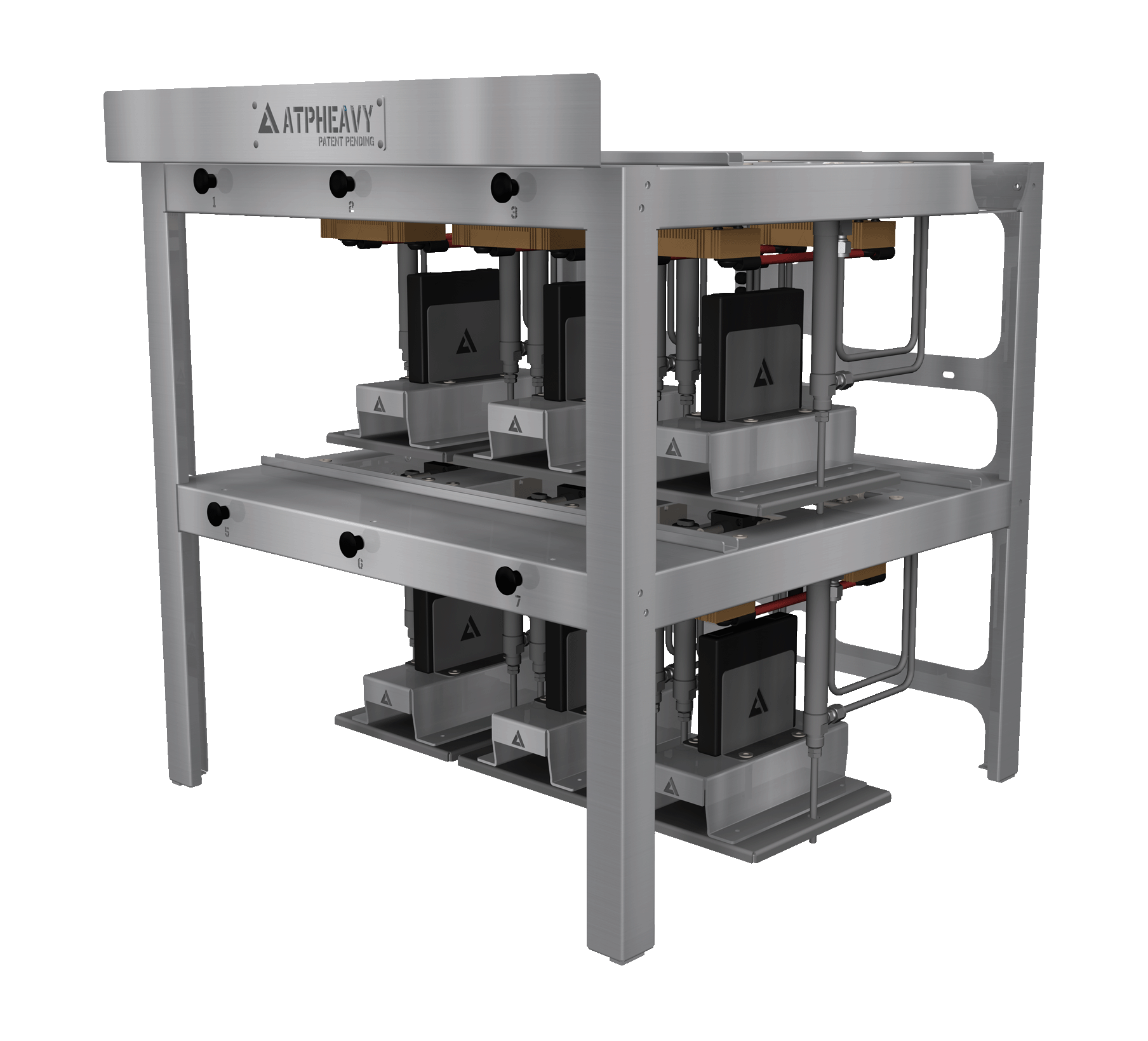

ATPHEAVY®

AES' patent-pending high amperage battery fixture is engineered to fit your testing needs, and is compatible with the SC-508-SAFE and the SC-512-SAFE. The ATPHEAVY is the only large cell testing fixture of its kind.

Featuring: Prismatic 8 Channel

Featuring: Prismatic 6 Channel

Specs at a Glance

- Application: High Current

- Cell Format: Prismatic and Cylindrical

- Maximum Current: 1000 Amps

- Cable Management: High-amperage Cables, Direct Wire, and Cable Chain

Efficiency Meets Reliability

At AES, we prioritize efficiency and reliability in every product we create. Our High Current Power Solution is meticulously designed to deliver seamless power, reduce downtime, and enhance productivity. Trust our solution to keep your operations running smoothly.