Environmental Test Chambers for Corrosion Testing

Corrosion is a natural process that impacts product longevity. It’s triggered by factors such as moisture, temperature fluctuations, acidity, and salt—conditions that exist in various environments. While corrosion can't be fully prevented, it can be controlled with effective product design and comprehensive testing.

Industries rely on salt spray or also known as salt fog chambers to assess a product's resistance to corrosion. These chambers help engineers create more durable products by simulating corrosive conditions, enabling them to forecast the lifespan and performance of their designs.

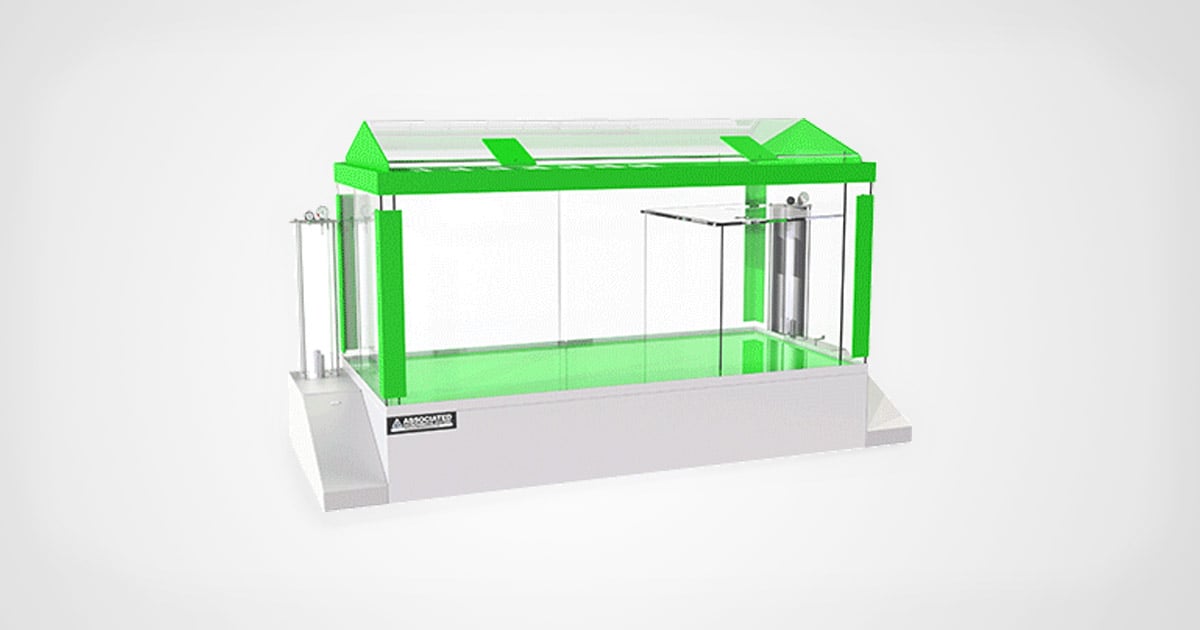

Associated Environmental Systems (AES) manufactures corrosion test chambers, also known as salt spray chambers, for businesses ranging from electronics to the automotive industry. The MX Series offers a unique set of features, including superior observation capabilities. Completely self-contained, the MX Series salt spray chambers enable test items to be subjected to a corrosive environment without introducing other contaminants into the test area—the DUT visible from almost any angle.

What is the Price of a Salt Spray Chamber?

The price of a salt spray chamber varies depending on a number of factors, including size and performance. Small chambers are less expensive than larger ones. The same is true for chambers designed for steady-state, or stability testing compared to cycling.

A good rule of thumb is that a quality, standard humidity chamber costs between $17,000 and $30,000. This base price often increases with customizations and optional features (such as dry air purges or recirculating desiccant air dryers). Work with a manufacturer to build a humidity chamber that fits your needs.

Industries That Rely on Salt Spray Chambers

Corrosion chambers are essential tools in product development and quality assurance across a wide range of industries. These chambers enable engineers and researchers to replicate harsh environmental conditions—like salt spray, humidity, and acidic atmospheres—to evaluate a product’s durability, longevity, and resistance to corrosion. Whether you're testing metal components, coatings, or electronics, our chambers are engineered to meet your exact specifications and ensure long-term performance.

Explore how corrosion testing plays a role in each industry:

-

Automotive: Validate battery safety and performance under thermal stress.

-

Pharmaceutical: Ensure product integrity and shelf-life through stability testing.

-

Packaging: Comprehensive testing to guarantee your packaging effectively protects your product during transit and storage

-

Consumer Products: Simulating the thermal stresses everyday products.

-

Paints & Coatings : Ensue the quality and longevity of your products.

Want to learn more about how we support each industry? Explore the industries we serve to see how our solutions align with your specific needs.

MX Series Corrosion Chambers

The MX Series is completely self-contained; the MX Series salt spray chambers enable test items to be subjected to a corrosive environment without introducing other contaminants into the test area, making the DUT visible from almost any angle. This corrosion-mimicking process is observable, again, through 360-degree high-quality Lucite®️ plexiglass.

To ensure temperature uniformity in the test workspace, chambers in the MX Series use two separate RTD sensors.

Tower Temperature: 45.5°C (114°F).

Chamber Temperature: 35°C (95°F).

Available Volumes: 3.38, 8, 15.63 cu ft.

Remote Monitoring with AESONE CONNECT®

AES MX Series chambers come standard with AESONE CONNECT®, a combination of hardware and software solution that enables you to monitor tests remotely. You can view real-time and historical data, create, edit, save, and move between test profiles from anywhere you can access a web browser.

Watching from a full-screen monitor, AESONE CONNECT® empowers you to design and rearrange tests with visually intuitive plot lines, clear data intervals, and colorful graphs. Furthermore, sharing a chamber is not a security problem. The administrator controls multiple login authentication methods and user-access permission levels and can establish expiration dates for each user.

Salt Spray Test Chamber Resources & FAQs

Associated Environmental Systems not only manufactures top-of-the-line salt spray test chambers customized to your needs but also provides resources to support your testing and keep you updated on the latest industry developments.

What are Salt Spray Chambers?

A salt spray chamber creates a highly corrosive environment to test the long-term effects of salt on objects and materials. Read More

What are Salt Spray Chambers used for?

Salt spray test chambers enable users to assess how resistant their products, components, or materials are to corrosion by isolating devices under test in a salt mist or fog over a specified amount of time. Read more

Salt Spray Chamber Start-up and Operating Procedures

Starting up and operating your salt spray test chamber is easy with the help of this article. Read more

Troubleshooting: Common Salt Spray Chamber Questions

Request More Info

Associated Environmental Systems is committed to long-term, responsive relationships with our customers. Looking to purchase a new chamber? Have questions about service, support, or retrofitting an existing chamber?

Don't hesitate to contact us with your questions or challenges.

Ready to get started?

Reach out now by phone, chat, or form submission. Our team is ready to help you!