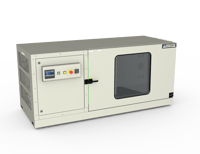

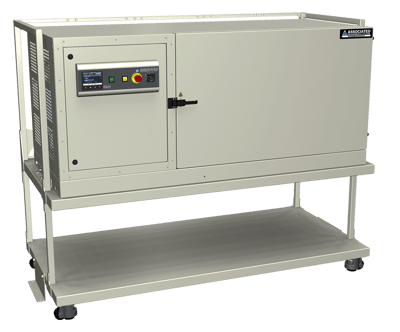

SC-512-4-SAFE Environmental Test Chamber

SC Series - Temperature Only

%20front%202X%20light.png?length=400&name=SD-512-4%20(Super)%20front%202X%20light.png)

%20front%202X%20light.png?length=90&name=SD-512-4%20(Super)%20front%202X%20light.png)

SC-512-4-SAFE

BenchtopRack and Stack

The SC-512-4-SAFE, also known as the Super 512, is the most powerful temperature-only benchtop test chamber in the world and is specifically designed with AES SAFE battery testing safety features to keep you safe up to EUCAR Hazard Level 7. The SC-512-4-SAFE can seamlessly integrate with our ATP® (All Test Platform) battery testing fixtures.

If you are concerned about losing your lab counter space, this test chamber has an optional floor stand for one chamber, or get double the test workspace when you stack two SC test chambers in the same footprint.

BATTERY SAFETY SYSTEMThe SC-512-4-SAFE is intentionally engineered and manufactured for battery testing, with specialized safety features designed to prevent battery events before they occur. Unlike general-purpose chambers, the SAFE SYSTEM prioritizes hazard prevention by incorporating temperature-limited sheath heaters, ensuring the heating elements remain below auto-ignition temperatures. Additional hazard prevention features include a rapid temperature rise feature to detect when a cell is heating abnormally utilizing the integrated safety thermocouples that can be placed directly on the cell. These sensors can also be used to detect a user selectable high cell temperature. User controls such as a maximum test setpoint temperature can also be configured to prevent test profile errors. While also incorporating robust mitigation features such as atmospheric inertization for fire suppression, a low flow pressure relief to vent cell gasses and a graphite rupture disc for pressure relief. For applications requiring a wider temperature range, an abuse testing configuration is available to support more extreme conditions while maintaining the highest safety standards. Battery Safety Features The SC-512-4-SAFE is equipped with all essential safety features to protect your lab and personnel.(See Safety Features tab for full details.)

STRUCTURE. The internal workspace is lined with type 304 stainless steel for a vapor-tight internal construction. Two specialized ports allow for cable patches to feed through the back of the test chamber workspace and easily connect to your battery cycler test equipment.

The exterior has a durable powder-coat finish over heavy-gauge steel for a long-lasting clean look. Between the two layers is highly efficient, low k-factor, thermal insulation. This chamber is built to last for many years.

CIRCULATION SYSTEM. Air circulation is crucial for environmental testing. The SC series has an increased air flow with two 1/3 horsepower motors and blower wheels with adjustable speed. This optimizes temperature conditions within the workspace for the ATPHEAVY battery fixture.

HEATING SYSTEM. SC test chambers feature heating systems equipped with temperature limited sheath heaters to maximize safety and performance for reliable and accurate temperature control within ±0.5°C.

COOLING SYSTEM. The cooling system in the SC series consists of a self-contained mechanical refrigeration system with a single stage configuration, and a 3.5 HP scroll compressor. An optional water-cooled condenser is available.

Add boost cooling with liquid LN2 or CO2 for even faster pull-down rates. It's a great option for stress tests that require rapid cooling.

Even without boost cooling, AES’ standard refrigeration systems have the fastest standard change rates of any environmental test chamber manufacturer. See Basic Specifications tab below.

INSTRUMENTATION. SC-512-4-SAFE Test Chamber incorporates AESONE CONNECT® creating a robust connected device giving you a standard and uniform interface that makes operation easier. Learn more in the Instrumentation Tab below.

- Specifications

- Standard Features

- Instrumentation

- Safety Features

- Optional Features

- Downloads

Specifications

SC Series

| Interior: | 36W x 24.1D x 25.8H (in) |

| 914.4W x 612.1D x 655.3H (mm) | |

| Exterior: | 88.5W x 40D x 36H (in) |

| 2247.9W x 1016D x 914.4H (mm) | |

| Volume: | 12.95 cubic ft |

| 366.7 liters | |

| Temperature: | -20°C to 80°C (-4°F to 176°F) |

| Electrical Supply: |

208 VAC, 1 PH, 60 HZ

(Optional) 230VAC |

| Full Load Amps: | 50 A |

| Facility Power Receptacle: |

6' cord with 2-Pole 3-Wire Grounding, Non-NEMA, Twist lock plug. CATALOG# CS8265C

|

| Refrigeration System: | Single stage |

| Mobility: | Will fit through 48 in doorway |

| Approximate Product Weight: | 925 lbs (420 kg) without added options |

*Rise and pull-down rates calculated using IEC 60068-3-5 standard. Custom options available.

*Ideal ambient temperature conditions for test chambers is 23°C (73.4°F). The temperature and humidity range of assured performance is between 15°C and 25°C (59°F/77°F) and 30-50% relative humidity. Conditions outside this range may affect the performance of your test chamber and reduce the lifespan of the equipment.

Notice for Customers Requesting R449A:

Consult our sales team regarding the use of R449A refrigerant (where applicable). This substitution ensures compliance with relevant regulations. Please be aware that the use of R449A will change the achievable low temperature to -35°C. Our sales team can provide detailed information regarding this change for your specific application.

Standard Features

STANDARD FEATURES

- External cabinet construction consists of heavy-gauge, cold-rolled steel with powder coat, bone color, and textured matte finish

- Interior cabinet constructed with type 304 stainless steel

- Exterior light with exterior switch on cabinet face and operable on AESONE CONNECT

- Port configuration: Two rear wall access port and plug with 4in (76.2mm) diameter for ATP fixture and four 2in (50.8mm) diameter rear wall ports for additional sensors

- Equipped with AES SAFE Battery Safety Features. Safe up to EUCAR Hazard Level 7. A full list of included safety features is listed in the safety features tab.

Instrumentation

STANDARD INSTRUMENTATION

CONTROLLER

SC Series Test Chambers have incorporated AESONE CONNECT® creating a robust connected device for a standard and uniform interface making test chamber remote monitoring easier.

AESONE XCHANGE is hardware internal to the chamber that increases your functionality

- Connects the test chamber controller to your network for increased accessibility

- On-board multi-year data logging

AESONE SOFTWARE gives you the power to

- Remote chamber operation and monitoring,

- Web-based test profile creation,

- Viewing current data and historical data visually

- Secure multi-level user access

ADDITIONAL ONBOARD INSTRUMENTATION

WATLOW F4T PROGRAMMABLE CONTROLLER. Features a 4.3” capacitive touchscreen minimizing the chance for error. Ethernet communication supported by AESONE HARDWARE. View more controller options

SENSORS

- TEMPERATURE SENSOR. Measured at the point of airflow entering the workspace. Class A, 3-wire, 100 Ohm Platinum RTD sensor

OPTIONAL DATA LOGGERS. View additional data loggers

Safety Features

STANDARD SAFETY FEATURES

Optional Features

OPTIONAL FEATURES

- Custom Porting Sizes

- LN2 Boost Cool

- CO2 Boost Cool

- Desiccant Air Dryer to reach conditions as low as 5% RH

- Gas Purge compatible with Dry Nitrogen (GN2) & Compressed Dry Air (CDA)

- Floor Stand with Casters

- Single Gas Sensor

- Dual Gas Sensor

- Triple Gas Sensor

- Large Burst Disk Upgrade

- Additional Thermocouples

Downloads

Similar Products

Please Try Again.