Temperature Chambers Solutions

Precise control over your environmental testing conditions

Browse ProductsAES Temperature Chambers: Built for Real-World Testing

Temperature chambers simulate the actual thermal extremes your products face—from sub-zero cold to intense heat and rapid cycling. AES chambers deliver the control and consistency you need to validate performance with confidence at any scale, from benchtop test chambers to walk-in rooms for full assemblies.

Built on decades of proven engineering, our chambers handle demanding protocols without compromise. Whether you're running steady-state conditioning or aggressive temperature cycling, AES delivers the precision and reliability your specific testing demands.

Explore AES Test Chamber Solutions

A Temperature-Controlled Chamber Engineered for Precision Testing

AES manufactures temperature chambers across four distinct series—from stackable benchtops to walk-in rooms—with specialized configurations for battery testing and space optimization.

- Extreme conditions – standard options from -37°C to +180°C or -70°C to +180°C with ±0.5°C precision

- Industry-leading speed – ramp rates from 3.9°C/minute to 9°C/minute and faster for aggressive cycling protocols

- Battery testing solutions – battery test chambers equipped with ATPPRIME, ATPHEAVY, or ATPFLEX testing fixtures

- Space optimization – stackable configurations and rack-mount options to maximize lab efficiency

AES Types of Temperature Chambers

AES offers the following series of temperature-only test chambers:

SD Series

The SD series benchtop temperature chamber is stackable, enabling you to optimize lab space and test more efficiently, including battery testing with an ATP fixture.

Temperature Range: -70°C to +180°C (-94°F to +356°F).

Available Volumes: 2 and 8 cu ft

SC Series

The SC Series features the most powerful benchtop chambers in the world. With their small footprint, these stackable temperature chambers enable you to optimize lab space and test more efficiently.

Temperature Range: -37°C to +180°C (-34.6°F to +356°F).

Available Volumes: 8 and 12 cu ft.

FD floor models feature fast change rates to conduct high-performance testing and cycling.

Temperature Range: -70°C to +180°C (-94°F to +356°F).

Available Volumes: 1, 2, 8, 10, 13, 18, 27, 36, 48, 64, 80, 96 cu ft.

FDR Series

The FDR Series allows you to test frequency-generating devices within a shielded environment, effectively shielding frequencies from entering and escaping the test chamber workspace.

Temperature Range: -37°C to +180°C (-34.6°F to +356°F).

Available Volumes: 1 and 5 cu ft.

Industries That Rely on Thermal Test Chamber Solutions

Temperature chambers are critical to product testing, development, and validation across a wide range of industries. Explore how temperature testing plays a role in each industry:

Explore how temperature testing plays a role in each industry:

-

Electric Vehicles (EVs): Validate battery safety and performance under thermal stress.

-

Pharmaceuticals Ensure product integrity and shelf-life through stability testing.

- Medical Devices: Verify performance and reliability of life-saving medical devices.

-

Energy Storage: Evaluate cell and pack performance under varying environmental test chamber conditions.

-

Aerospace: Simulate extreme environments to verify system components for in air travel.

-

Military & Defense: Meet strict military standards (MIL-STDs) with thermal testing.

Want to learn more about how we support each industry? Explore the industries we serve to see how our solutions align with your specific needs.

Temperature Chamber Systems

AES carries a wide variety of top-of-the-line temperature chambers from benchtops to walk-ins. You can also purchase rack-and-stack test chambers to maximize your lab space and optimize efficiency. Consider a chamber equipped with ATPPRIME or ATPHEAVY for the safest, most effective battery testing in the industry, or ATPFLEX, a battery testing fixture that can be installed into nearly any chamber.

Standard temperature ranges: -37°C to +180°C (-36.46°F to 356°F) | -70°C to +180°C (-94°F to 356°F)

Precision: ±0.5°C

Ramp Rates: 3.9°C/minute to 9°C/minute and faster

Heating System

The heating systems in AES chambers are all-electric and pass air over fast-response, low-watt-density resistance heaters with a ceramic core, ensuring a long, reliable life with no downtime. The combination of airflow, instrument response, and these fast-reacting heaters gives highly accurate and straight-line temperature control. These heating systems support temperatures upwards of 180°C (356°F), and heaters may be controlled independently or in unison. Heating systems are located in a plenum so that test items are not subject to direct radiation.

Cooling System

The cooling system in AES chambers consists of a self-contained mechanical refrigeration system with a cascade configuration. You’ll have the option of air-cooling or water-cooling. Air-cooling comes with easier installation and is less expensive than water-cooling. However, it produces slower pulldown rates.

Water-cooling systems result in faster pulldown rates and are more energy efficient, but they require a dedicated, conditioned water supply and are more complicated to install.

You can supplement your system with boost cooling employing liquid nitrogen (N2) or carbon dioxide (CO2) for even faster pull-down rates. It's a great option for stress tests that require rapid cooling. Even without boost cooling, AES standard cascade refrigeration systems have the fastest standard change rates of any environmental test chamber manufacturer.

Air Circulation

Air circulation is crucial for environmental testing. AES’s chambers have proprietary baffle and fan design combinations, which optimize temperature conditions within the workspace.

Safety Features

Temperature chambers come standard with a few key safety features. A high/low temperature control function enables you to adjust testing conditions so they do not exceed a certain temperature limit above or below what is set for the device under testing (DUT). This includes an internal high-temperature safety component and refrigeration system over-pressure safety circuit. These elements combine to help protect your product throughout the testing process.

Additionally, temperature chambers designed for battery testing come equipped with standard and additional safety features that are key in preventing thermal runaways. AES SAFE chambers have safety features rated up to EUCAR level 7. They protect products and labs and keep user safety in mind so you can innovate with confidence.

Radio Frequency Shielding

Some companies need to block radio frequencies during their testing because they can affect the performance and functionality of DUTs. This is also important for compliance. In the form of the Federal Communications Commission (FCC), the United States government strictly enforces safety restrictions on radio frequencies. The regulations cover everything from broadcast television and radio to satellite communications and aeronautical navigation.

AES builds some temperature chambers with RF shielding that features the following:

- Cellular, metallic, chromatic gaskets and conductive adhesives that seal the workspace

- A honeycombed RF-shielded grill that keeps the circulation motor cool

- Electrical wiring fed through special RF filters

- Standard and customer-requested RF-rated connectors, installed on a side-mounted interface plate to provide a shielded pass-through grid so you can communicate with the DUT

The level of attenuation (the strength of the signal the test chamber blocks and, by extension, isolates) varies as well. Each test chamber is certified by an independent facility prior to being shipped.

Battery Testing in Temperature Chambers

Advancements in battery technology—how they’re made, shaped, and used—require rigorous testing for safety, performance, and reliability. Companies utilize temperature chambers, and sometimes humidity chambers, for this purpose.

The results are often world-changing. Rechargeable batteries power not just our cell phones, tablets, and laptops but also medical devices, drones, and more. Increasingly, companies are investing significant time and resources into developing longer-lasting, faster-charging batteries for electric vehicles to help manufacturers meet consumer demands and achieve their carbon emission goals.

All of these batteries must be evaluated before being packaged or included in a device shipped to market.

AES has designed battery test chambers (with extensive safety features) to expand a company’s ability to conduct battery research and development in controlled conditions, enabling them to innovate toward a brighter future.

Patented ATPPRIME

The patented ATPPRIME, available in several AES temperature chambers, enables testing of almost any battery format, including coin, cylindrical, pouch, prismatic, and pack cells. The fixture can seamlessly rotate between battery types using universal Kelvin connectors. Each connector is safely accessed by sliding shelves capable of accommodating loads holding up to 48 cells across four levels.

Patent-Pending ATPHEAVY

ATPHEAVY enables testing of up to 1000 amps per channel. It is designed specifically to accommodate large prismatic and pouch cells that power electric vehicles. In addition, ATPHEAVY ADAPTABLE is a first-of-its-kind solution. The modular board allows your custom-tailed future to support different amperage, cell sizes, and formats. With one adjustable fixture, you can conduct all your high-amperage testing needs in a single chamber.

Both the SC-512-4-SAFE and SC-508-SAFE, two of the most powerful benchtop temperature chambers in the world, can be equipped with ATPHEAVY or ATPHEAVY ADAPTABLE. You can also stack multiple chambers to maximize testing efficiency.

Watch AES ADVANTAGE featuring ATPHEAVY ADAPTABLE

Do you already have an environmental chamber and want to test batteries? Explore ATPFLEX, a fixture that can be integrated into your chamber and capable of testing coin, cylindrical, pouch, prismatic, and pack cells.

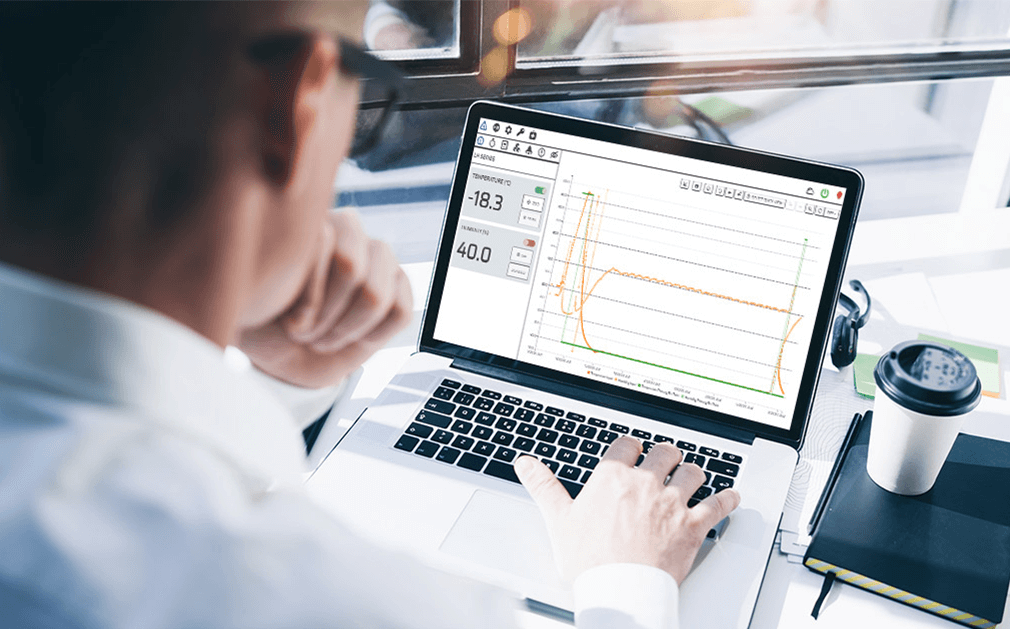

Remote Monitoring With AESONE CONNECT®

AES temp chambers come standard with AESONE CONNECT®—monitor and control your tests from anywhere with web browser access.

- Real-time control – view live data, create test profiles, and adjust parameters remotely

- Visual analytics – intuitive plotlines, graphs, and historical data tracking on any device

- Multi-user management – administrator controls for authentication, permissions, and access expiration

- Retrofit Capability- Add AESONE Technology to nearly any existing chamber in your facility.

Temperature Chamber Resources & FAQs

What is a temperature chamber?

A temperature chamber, also called a thermal test chamber, creates controlled hot and cold environments to evaluate how products perform under specific temperature conditions. These chambers help engineers validate performance, reliability, and safety across industries from electronics and batteries to aerospace and medical devices.

How does a temperature thermal chamber work?

A temperature chamber uses integrated heating and cooling systems, sensors, and airflow controls to maintain precise thermal conditions inside a sealed workspace. They are designed for tight temperature uniformity and rapid ramp rates, ensuring consistent, repeatable results throughout each test.

What temperature ranges do temperature chambers cover?

Most temperature chambers operate from –70 °C to +180 °C, with certain models extending beyond these limits for specialized testing. Custom-designed configurations can accommodate a wider chamber temperature range or integrate humidity and safety systems for more complex temperature and humidity environments.

What is the difference between a temperature chamber and a climate chamber?

A temperature chamber controls only heat and cold, while a climate chamber adds humidity testing and regulation to simulate broader environmental conditions. Choosing between them depends on whether humidity is a critical factor in your testing program.

What is a temperature cycle chamber?

A temperature cycle chamber repeatedly heats and cools a test item to simulate real-world thermal stress over time. These chambers feature programmable profiles and fast transition rates to accelerate durability and fatigue testing.

What is a high-precision temperature chamber?

High-precision temperature chambers maintain extremely tight tolerances—often within fractions of a degree—to support tests requiring exact thermal stability. They are commonly used in industries that demand the highest accuracy, such as electronics, aerospace, and battery research.

What factors should be considered when buying a temperature test chamber?

Key considerations include temperature range, uniformity, ramp rate, chamber size, and the thermal load of your samples. Selecting the right model also depends on performance goals, available space, and long-term maintenance requirements.

Troubleshooting: Common Temperature Chamber Questions

- What preventative maintenance should I perform on my chamber’s refrigeration system?

- What preventative maintenance should I perform on my chamber’s electrical system?

- How fast can my chamber ramp up and pull down?

- Why does my chamber not have a temperature pull-up?

- Why does my chamber have a temperature pull-up above the controller setpoint?

- Why is there poor air circulation within my chamber?

Ready to get started?

Reach out now by phone, chat, or form submission. Our team is ready to help you!

.png?width=365&height=282&name=SD-508%20(2).png)