About Associated Environmental Systems

Environmental test chambers for nearly every industry

Associated Environmental Systems was founded in 1959 in Wayne, New Jersey, with the goal of making sophisticated test chambers capable of meeting the most demanding testing requirements.

Since then, AES has become an innovative industry leader with divisions on the East Coast, West Coast, and Midwest. We’re proud to distribute environmental chambers globally and across nearly every commercial industry.

The AES Way

We design, manufacture, support, and service robust environmental chambers and battery testing fixtures you can rely on.

From humidity and temperature chambers to salt spray and thermal shock chambers, the world’s top companies depend on us for their testing solutions. We have the ability to optimize the type of testing that works specifically for your situation, including small benchtop chambers to very large walk-in units, saving you substantial time and money.

Environmental Chambers

Nearly every commercial industry relies on environmental test chambers. Rain or shine, extreme heat or cold, rough and tumble, AES chambers put your products and components through the most rigorous of tests to ensure they function as expected.

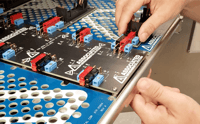

Patented Battery Testing Fixtures

Batteries power our most-beloved devices, but these technologies wouldn’t be possible without innovations in battery testing, such as our patented battery fixtures. ATPFLEX, ATPHEAVY, and ATPHEAVY Adaptable can accommodate an extensive assortment of battery shapes and types. We offer battery testing solutions for almost any situation.

Service

Keeping up a regular maintenance schedule can dramatically extend the life of your test chamber. Our experts are here to help service your chambers, whether they’re manufactured by us or somebody else.

Our Values

1. Design

Our team of skilled SolidWorks and AutoCAD design engineers create 3D renderings and ensure your specifications are met before manufacturing begins. Our detailed schematics guarantee each component looks and operates as it should.

2. Efficiency

Our turnaround times are rapid. In addition to keeping standard chambers in stock, our custom environmental chambers are built using computer-guided lasers with unparalleled precision and welding expertise, reducing lead time.

3. Dependability

That AES logo on your chamber lets you know our entire team is behind you. Over-the-phone testing consultation, in-person maintenance, or on-site repairs, we’re there for you. We’ll even order the spare parts you need and install them for you.

4. Integrity

Your confidentiality is our priority, and our policies assure you that both the highest quality and social standards are met and maintained. Always.

Our Leadership Team

Michael Shirley

CEO

Aaron Robinson

VP of Sales

Brockton Kenyon

CTO

Anthony Petrillo

Director of Accounting

Peter Kershaw

Director of Operations

Craig Algier

Director of Engineering

Haylie Batres

Director of Marketing

Michelle Coffey

Director of People Operations

Justin Ingram

Quality Manager

Mike Johnson

National Field Service Manager

Careers

AES looks for driven individuals to join its team in fields like mechanical and software engineering, manufacturing, customer service, and more.

The AES Story: Our History

2005

AES introduced and developed our All Test Platform (ATP) battery testing fixture. A system for testing high density cells in a controlled environment.

2014

AESONE CONNECT was created. AESONE CONNECT is a combination of hardware and software that allows you to remotely monitor your chamber from anywhere, on a desktop laptop, or tablet

2016

We move into a 50,000 square-foot manufacturing facility in Acton, MA, with more than 20,000 square feet of office space for our passionate team.

2025

We’re proud to introduce FUSION, a fully integrated battery testing system, developed in partnership with Maccor.

Locations

East Coast

HEADQUARTERS

Sales and Service

978-772-0022

15 Wellman Ave, North Chelmsford, MA 01863

Midwest

Sales and Service

Detroit and Grand Rapids

West Coast

Sales and Service

1446 Franklin Street

Santa Clara, CA 95050