Walk-In Chambers

We offer panel and structural walk-in test chambers

A typical environmental walk-in test chamber.

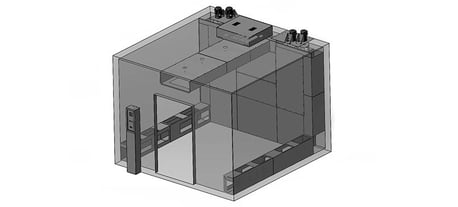

A solid-steel structural walk-in room holds two server racks. High-performance change rates even with live loads.

A walk-in unit designed to test lottery slot machine requiring extra vertical footage.

Sliding doors can be beneficial on chambers being used to test cars and small planes.

View Walk-In Chambers

A FULL RANGE OF RELIABLE WALK-IN ENVIRONMENTAL TEST CHAMBERS

STABILITY CHAMBERS • TEMPERATURE & HUMIDITY PERFORMANCE CHAMBERS • EXTENDED PERFORMANCE CHAMBERS • HIGH LIVE LOAD CHAMBERS

Associated Environmental Systems has a full range of walk-in chambers. Whether you are storing many small products on carts, creating a controlled workspace for research and design, or if you need to drive large vehicles in for testing, at AES, we have a walk-in chamber for every need.

Prefabricated, tight-tolerance environmental walk-in rooms are ideal for large or oddly shaped objects and workspaces with tight environmental controls. Our history of building long-lasting, durable environmental test chambers and large-scale walk-in rooms with precise control and reliability can give you peace of mind that you can test anything from an entire car to 10,000 cell phone units.

Depending on your temperature and humidity chamber requirements and the load, each walk-in environmental chamber can be installed using a removable panel system or as part of a more permanent structural build.

INDUSTRIES THAT RELY ON WALK-IN CHAMBERS?

Walk-ins ensure control and reliability across industries. Designed to accommodate large items or materials, walk-ins make testing possible for objects where space is typically a constraint.

Explore how walk-in testing plays a role in each industry:

- Automotive: Simulated various conditions to verify the performance of large vehicles and their components.

- Packaging: Expose materials to a consistent environment to determine shelf life and potential vulnerabilities.

- Consumer Electronics: Identify design flaws through a controlled environment before a product is released to consumers.

- Aerospace: Evaluate the performance of aircraft components to meet safety standards and regulations.

- Pharmaceuticals: Ensure the quality and durability of medications through stability testing.

Want to learn more about how we support each industry? Explore the industries we serve to see how our solutions align with your specific needs.

STABILITY WALK-IN CHAMBERS

When products need to be tested or stored in a constant environment, stability chambers will replicate such conditions.

When products need to be tested or stored in a constant environment, a walk-in stability chamber will replicate such conditions. Stability chambers are meant to run constantly for long periods of time at a consistent temperature with or without humidity.

Each walk-in climatic chamber is electronically configured to meet several governmental regulations and test requirements in industries such as electronics, healthcare, food and beverage, packaging, life science, and more. Chambers are always factory set and configured to meet your specific test requirements, and a service team member can calibrate the chamber to ensure accuracy.

Below are common sizes manufactured at Associated Environmental Systems in Acton, Massachusetts. We are known for building custom stability chambers that meet our customers' specifications and have the same manufacturing lead times as standard chambers.

| Common Standard Sizes | Stability Performance | |||

|---|---|---|---|---|

| Working Volumeᵗ | Exteriorᵗ | Temperature Only* or Temperature & Humidity* | ||

| 264.8 cu ft (7,498.3 L) Interior: 52X88X100 in |

60X96X116 in | Standard Range -40°C to + 85°C | Extended Cold Range -65°C to +85°C |

Extended Hot Range -40°C to +150°C |

| 337.9 cu ft (9,568 L) Interior: 52X112X100 in |

60X120X116 in | Standard: 3.5HP, Air-Cooled Unit Optional: Water-Cooled Unit Specify your needs, and an Associated Environmental Systems Engineer will work with you to calculate your needs for temperature systems or a dual temperature and humidity system. The blue range in the chart below is most common. However, other configurations are available. |

||

| 485.1 cu ft (13,736 L) Interior: 88X88X108 in |

96X96X124 in | |||

| 617.4 cu ft (17,482.8 L) Interior: 88X112X108 in |

96X120x124 in | |||

| 785.8 cu ft (22,251.4 L) Interior: 112X112X108 in |

120X120X124 in | |||

| 954.2 cu ft (27,019 L) Interior: 136X112X108 in |

144X120X124 in | |||

| 1,122.6 cu ft (31,788.5 L) Interior: 160X112X108 in |

168X120X124 in | |||

*Temperature and humidity at sensors ᵗAdditional WidthXDepthXHeight configurations available

WALK-IN PERFORMANCE CHAMBERS

Performance chambers are used for iterative testing where conditions fluctuate.

Chambers are available in more than two dozen sizes and can be combined with many power packages. Below is a small sampling of our most common chamber sizes with associated power packages to help you understand the performance options available to you. The matrix allows you to choose by size or by performance needs.

Standard Temperature Range

Temperature Only -37°C to +85°C

Temperature & Humidity -37°C to +85°C

| Common Standard Sizes | Standard Performance | |||||

|---|---|---|---|---|---|---|

| Working Volume † | Exterior † | Temperature Only -37°C to +85°C Temperature & Humidity -37°C to +85°C |

||||

| Rate of Change Key** Thruster: 0.0-1.49°C/min Impulse: 1.50-2.74°C/min Warp: 2.75°C/min + |

3.5HP Scroll, Single, Air Cooled |

6HP Scroll, Single, Air Cooled |

7.5HP Scroll, Single-Stage, Air Cooled |

15HP Scroll or Discus, Single, Water Cooled |

30HP Discus, Single-Stage, Water Cooled |

|

| 264.8 cu ft (7,498.3 l) Interior: 52x88x100 in |

60x96x108 in | 1.39°C/min | 1.55°C/min | 1.89°C/min | 2.23°C/min | 3.18°C/min |

| 337.9 cu ft (9,568 l) Interior: 52x112x100 in |

60x120x108 in | 1.23°C/min | 1.39°C/min | 1.72°C/min | 2.09°C/min | 3.06°C/min |

| 485.1 cu ft (13,736 l) Interior: 88x88x108 in |

96x96x108 in | 1.07°C/min | 1.23°C/min | 1.55°C/min | 2.10°C/min | 2.93°C/min |

| 617.4 cu ft (17,482.8 l) Interior: 88x112108 in |

96x120x108 in | 0.95°C/min | 1.10°C/min | 1.41°C/min | 1.95°C/min | 2.80°C/min |

| 785.8 cu ft (22,251.4 l) Interior: 112x112x108 in |

120x120x108 in | 0.83°C/min | 0.98°C/min | 1.27°C/min | 1.81°C/min | 2.67°C/min |

| 954.2 cu ft (27,019 l) Interior: 136x112x108 in |

144x120x108 in | 0.75°C/min | 0.89°C/min | 1.16°C/min | 1.68°C/min | 2.55°C/min |

| 1,122.6 cu ft (31,788.5 l) Interior: 160x112x108 in |

168x120x108 in | 0.68°C/min | 0.81°C/min | 1.06°C/min | 1.57°C/min | 2.43°C/min |

| Options Water Cooled Unit; Remote Air Cooled; Remote Consensing |

Options Remote Air Cooled; Remote Condensing (Scroll Only) |

Options Remote Air Cooled |

||||

*Temperature and humidity at sensor, **performance based on empty chamber, 10% from the top and 10% bottom on manual control, 108° workspace height. † Additional WidthxDepthxHeight configurations available.

Extended Temperature Range

Temperature Only -65°C to +150°C

Temperature & Humidity -65°C to +150°C

| Common Standard Sizes | Extended Cold Performance | |||||

|---|---|---|---|---|---|---|

| Working Volume † | Exterior † | Temperature Only -37°C to +85°C Temperature & Humidity -37°C to +85°C |

||||

| Rate of Change Key** Thruster: 0.0-1.49°C/min Impulse: 1.50-2.74°C/min Warp: 2.75°C/min + |

3.5HP Scroll, Cascade, Air Cooled |

6HP Scroll, Cascade, Air Cooled |

7.5HP Scroll, Cascade, Air Cooled |

15HP Scroll or Discus, Cascade, Water Cooled |

30HP Discus, Cascade, Water Cooled |

|

| 264.8 cu ft (7,498.3 l) Interior: 52x88x100 in |

60x96x108 in | 0.28°C/min | 0.65°C/min | 2.62°C/min | 4.16°C/min | 5.56°C/min |

| 337.9 cu ft (9,568 l) Interior: 52x112x100 in |

60x120x108 in | 0.27°C/min | 0.61°C/min | 2.35°C/min | 3.83°C/min | 5.26°C/min |

| 485.1 cu ft (13,736 l) Interior: 88x88x108 in |

96x96x108 in | 0.25°C/min | 0.57°C/min | 2.08°C/min | 3.48°C/min | 4.92°C/min |

| 617.4 cu ft (17,482.8 l) Interior: 88x112108 in |

96x120x108 in | 0.23°C/min | 0.54°C/min | 1.86°C/min | 3.18°C/min | 4.61°C/min |

| 785.8 cu ft (22,251.4 l) Interior: 112x112x108 in |

120x120x108 in | 0.22°C/min | 0.5°C/min | 1.65°C/min | 2.89°C/min | 4.30°C/min |

| 954.2 cu ft (27,019 l) Interior: 136x112x108 in |

144x120x108 in | 0.20°C/min | 0.47°C/min | 1.49°C/min | 2.65°C/min | 4.03°C/min |

| 1,122.6 cu ft (31,788.5 l) Interior: 160x112x108 in |

168x120x108 in | 0.19°C/min | 0.44°C/min | 1.36°C/min | 2.45°C/min | 3.79°C/min |

| Options Water Cooled Unit; Remote Air Cooled; Remote Consensing |

Options Remote Air Cooled; Remote Condensing (Scroll Only) |

Options Remote Air Cooled |

||||

*Temperature and humidity at sensor, **performance based on empty chamber, 10% from the top and 10% bottom on manual control, 108° workspace height. † Additional WidthxDepthxHeight configurations available.

Features

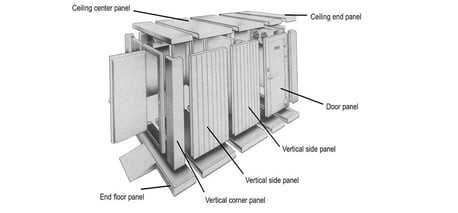

Panel Build

You gain most flexibility with self-supported, panel-construction, walk-in chambers as they allow for free-standing, self-supporting units that are cost-effective and efficient. Panelized construction allows the installation to fit through most doorways as it is assembled on-site. Panel thickness, flooring, and door size are interchangeable to meet your environmental testing needs; and there are several options that allow you to get the ports and viewing-windows, and accessibility you are looking for.

Panel construction made of a high-quality, polyurethane-injected core with a polyurethane frame for a highly-dense, 2.5 pounds per cubic foot, substrate that is 101 millimeters thick. With an

Structural Build

When you require extreme temperatures and saturated humidity rates your testing is more suited to structural build construction. Structural walk-in rooms are welded, one-piece units assembled with steel making them optimal for heavy or over-sized product loading and high humidity. Because of the solid steel construction, you also get the added benefit of long-term durability. Structural walk-in rooms are advantageous for speedy temperature change rates, high humidity, and explosion resistant applications.

In high-humidity conditions where increased pressure is present, a welded-steel structural frame interior is required. Under these reinforced conditions, temperatures from -73°C to +538°C (-100°F to +1000°F) can be sustained. And relative humidity can range from 10-95%.

Structural build chambers are always custom products and will not increase delivery time, but they do require more planning and engineering design time to create the plans and drawings followed by customer approvals before manufacturing can begin.

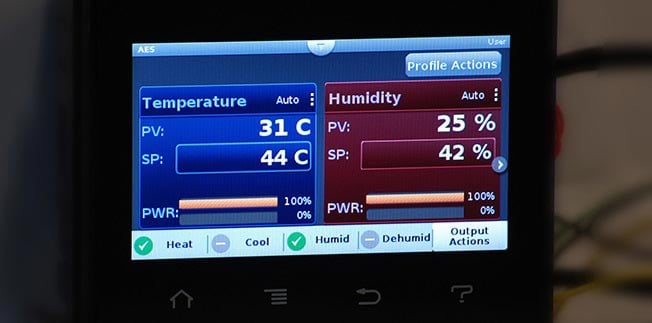

Control System

The Watlow F4T with AESONE CONNECT, is standard on all walk-in chambers and offers the easiest way to manage your walk-in chamber. The F4T's state-of-the-art control system provides easy operation and flexibility through an intuitive, user-friendly touch-screen interface at the chamber. AESONE CONNECT® features a browser-based dashboard that allows you to monitor processes, operate the chamber, and visually drag-and-drop to build profiles from your desk or remotely on your laptop or tablet. Your IT security team will appreciate that your chamber poses no network security risk due to its microprocessor architecture with secure firmware and the absence of Windows or Linux-based controllers. Our published API utilizes a standard REST-Like JSON API for easy communication, and we provide Python script examples.

The Watlow F4 controller is ideal for multi-step ramp and soak operation. The F4 enables you to create profiles to automate steps and events at the chamber. Add AESONE CONNECT® to remotely start, pause, stop, and monitor your product via live graphing and data storage.

AESONE CONNECT®

The dashboard is a remote, network-based method for controlling your walk-in chamber

- Network securely

- Monitor test cycles from your desk or remotely

- View data in real time

- Pause, stop, start, reset remotely

- Lock and unlock operation

- Allow multiple users six levels of access

Circulation System

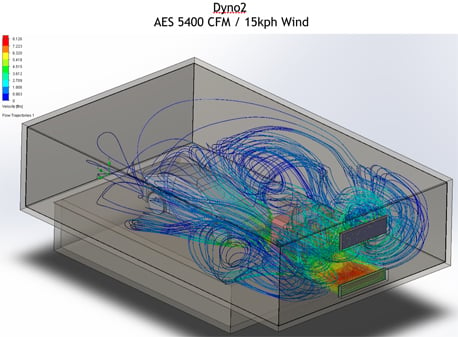

All AES walk-in environmental test chambers incorporate forced air circulation which uses external heavy-duty motors with internal cooling fans, protectors, and stainless steel shafts. Stainless steel squirrel cage bowers circulate the air, all mixing is accomplished with a plenum placed to create airflow patterns to accommodate your product size and arrangement within the room. Internal or external air plenums and horizontal, vertical or a combination of both are offered. Customizing the plenum space like this creates an evener distribution of air, closer temperature control for rooms with modest live loads and airflow, and where noise is a consideration with people working within the room.

DISCHARGES

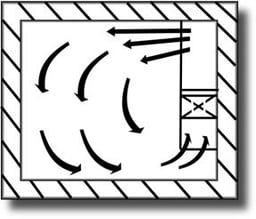

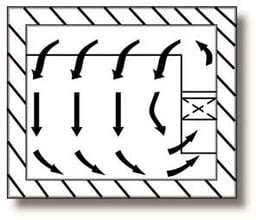

Horizontal airflow (left) results in very even cross flow of air, leading to good conduction with the test product surface. Vertical flow (right) results in more dynamic airflow which better mimics the multiple air speeds encountered in the natural world.

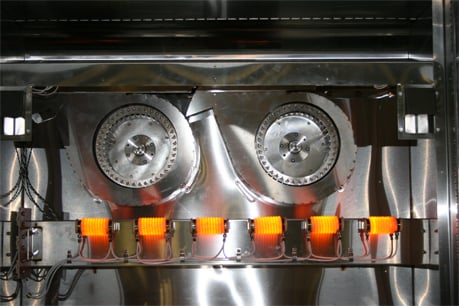

Heating System

Ceramic electric heaters are designed and custom-made for AES environmental chambers. These heaters have incredibly fast response rates and are assembled to be controlled independently ensuring the right amount of heat is maintained for your test application. Ceramic heaters also have long lifespans lowering your downtime and maintenance/repair costs. Your profiles will run with high accuracy because our uniquely separate instrument controls for air and humidity control. Together, the team of low-watt-density resistance heaters allows for various ranges and provide the fastest change rates.

Refrigeration System

AES modules use only Copeland compressors, a leader in the refrigeration industry. The scroll and discus compressors are hermetically and semi-hermetically sealed for low maintenance and longer run-times. The performance of sealed compressors increases energy savings, reduces noise, and lowers carbon footprints. Scroll compressor design allows for variable load demands of the room and can operate continuously in cooling mode and a with a full range of evaporating capabilities.

Air cooled or water cooled units can be installed on-top, behind, beside, or remotely to meet your space requirements. Remote units can be placed outdoors on exterior walls adjacent to the walk-in units to save prime laboratory real estate and create better working conditions for employees working in close proximity to an environmental chamber.

Humidity System

The vapor generator is a closed steam generator built in-house for your chamber’s requirements. This means they are sized to fit the chamber’s size. This translates to quicker steam generation and faster conditioning of the air in the workspace. The humidity range on most test chambers is 20% to 85% +/-2% RH (Relative Humidity). The range can be extended to 5% RH with the use of an optional dry air purge. Steam Generator Systems are best at achieving high-temperature/high-humidity conditions, where it is critical for the RH in the workspace to stay consistent.

Installation Services

AES is happy to work with local moving and rigging companies and within local building codes to safely and effectively install a product testing chamber. For large walk-in models, loud and spacious condensing and compressing units may be installed outside the building or on the roof to decrease decibels produced by the chamber and save space.