Environmental Chamber Maintenance

Keep Your Chamber Running at Peak Performance.

Decades of Industry Experience. Lifetime AES Support. Servicing All Chambers, Any Brand.

Environmental Test Chamber Preventative Maintenance Services

Unplanned downtime leads to delayed testing, missed deadlines, and lost revenue. Associated Environmental Systems (AES) offers routine and scheduled quarterly and annual preventative maintenance (PM) services to keep your test chambers operating reliably year after year.

Our maintenance programs help extend the life of your equipment, prevent costly repairs, and support consistent, compliant testing. Learn how AES can support your test chamber’s long-term performance.

WHY IS PREVENTATIVE MAINTENANCE IMPORTANT?

Even minor system issues can snowball into major disruptions. Routine environmental test chamber maintenance helps identify and resolve small inefficiencies before they become critical problems. Common issues we help prevent include:

-

Poor airflow and circulation

-

Dust or debris buildup

-

Mineral contamination in humidity systems

-

Drainage failures

-

Interior corrosion

-

Compressor breakdowns

-

Temperature control malfunctions

Avoid these setbacks by investing in routine performance checks and scheduled maintenance visits from AES-certified technicians.

What’s Included in an AES Maintenance Visit?

During each scheduled visit, our expert team performs a comprehensive inspection of your chamber’s core systems. Depending on your chamber type, our preventative maintenance service can include up to 85 specific checks. These typically cover:

-

Verifying chamber performance and functionality

-

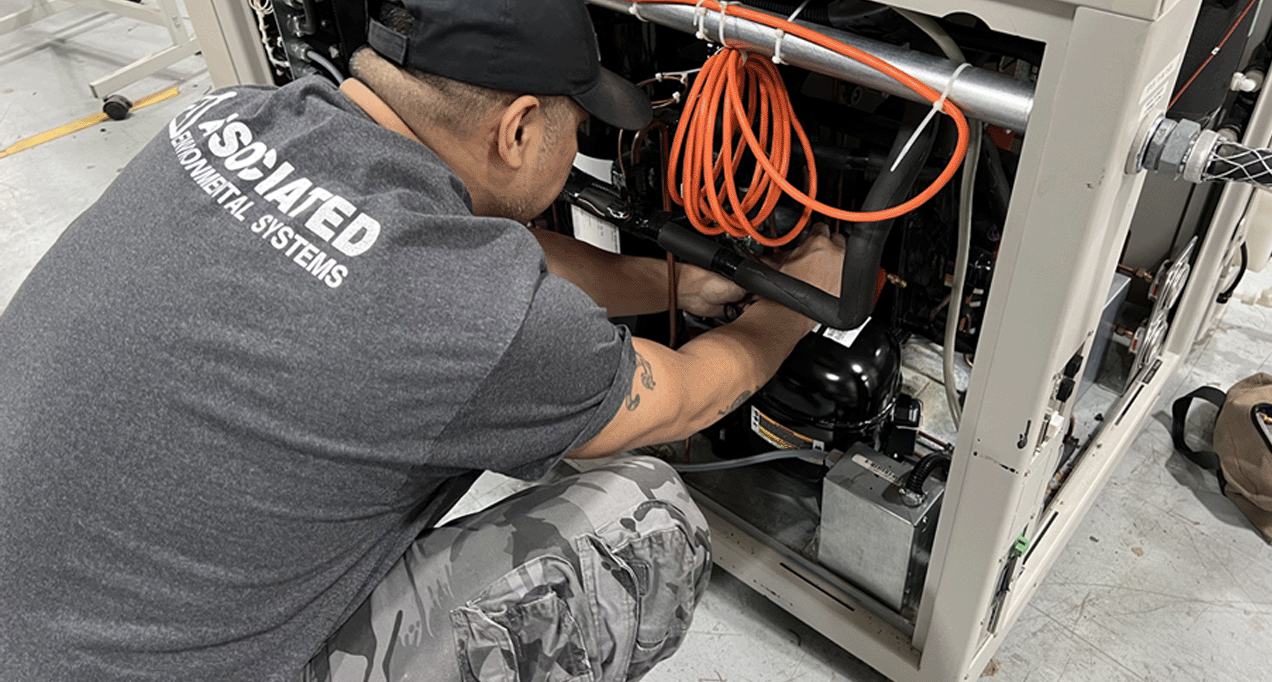

Checking refrigeration and humidity systems for proper operation

-

Evaluating refrigerant charge, line pressures, and temperature ranges

-

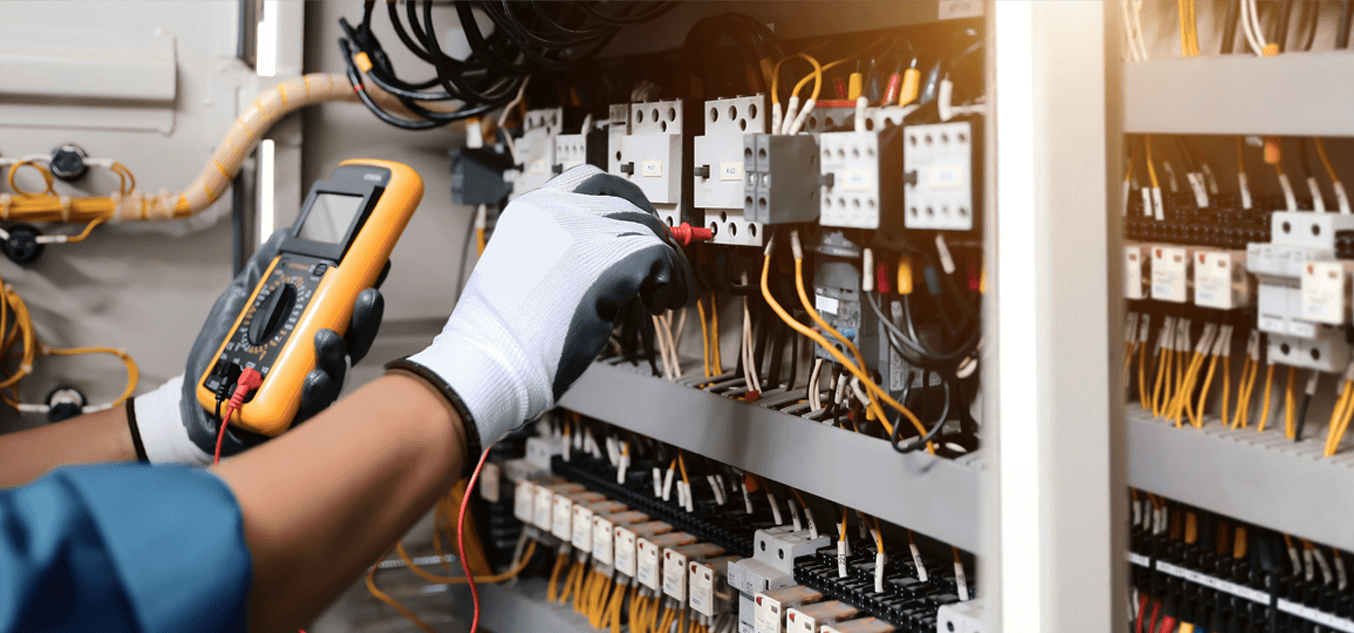

Assessing electrical components, voltage, and amperage levels

-

Performing ISO/IEC 17025 accredited calibration (as needed)

-

Identifying potential signs of wear, stress, or part failure

Our technicians will also provide maintenance documentation and recommendations for future service needs.

AES Preventative Maintenance Plans

We offer flexible PM agreements to match your test schedules and compliance needs:

-

Quarterly Maintenance Plans for high-use or critical test applications

-

Annual Maintenance Plans for standard chamber upkeep

-

Custom plans available for multi-chamber facilities or remote labs

AES supports test chambers of all types and from all manufacturers—not just our own.

Keep it Running- 40 years

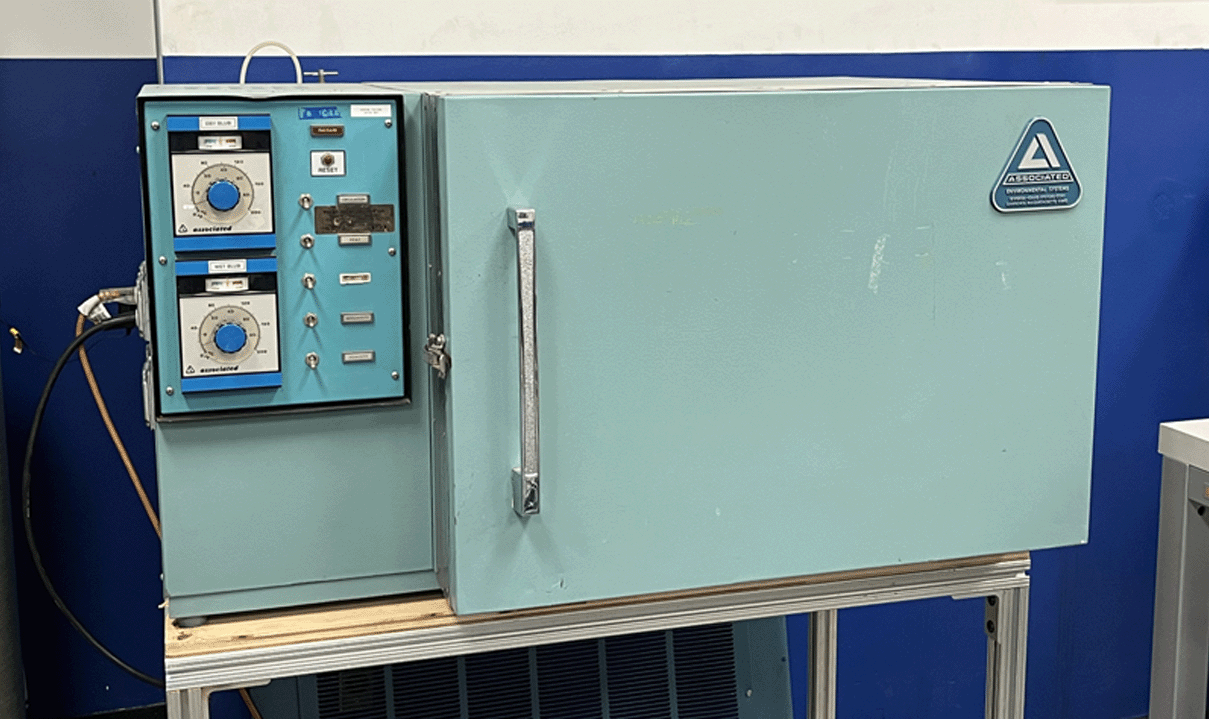

A consumer electronics company needed a humidity test chamber to ensure their components could withstand harsh environmental conditions. Compliance with IEC 60068 and IEC 62133 standards was critical.

Back in the 1980s, they turned to AES and purchased a BHD benchtop humidity chamber—compact, stackable, and built for long-term use.

What They Did

To protect their investment, the customer implemented a preventative maintenance routine:

-

Quarterly in-house system checks and cleanings

-

Regular gasket inspections and part replacements

-

Running the chamber during off-seasons

-

Denim cartridge replacements

They also scheduled annual calibrations with AES to ensure continued accuracy and compliance:

-

Controller calibrations

-

Single and Multi-point sensor validations

The Results

- Zero major breakdowns in over 40 years

- Continued testing accuracy and IEC compliance

- Avoided costly delays and production downtime

- Ready for future upgrades with AES retrofit options

Want to get the most out of your test chamber? Invest in routine maintenance and calibration with AES service experts, just like this customer did!

Resources & FAQS

What is the recommended timeline for preventative maintenance?

It’s best practice to receive quarterly preventive maintenance services and calibrations every six months to a year. For critical applications, though, or mandated regulatory standards, you may need to get your chamber serviced more frequently, such as quarterly. To keep your test chamber running smoothly, you should stay on schedule with your test chamber services.

Do I need to turn off the test chamber during maintenance fully?

To ensure safety and the best results, you should always shut your chamber completely off during maintenance.

What signs indicate my test chamber needs service?

If your test chamber is beginning to show signs of imminent repair, there may be water leaks, rust, corrosion, pooling, or condensation—just to name a few issues. It’s important to get help right away.

Does AES have any resources on doing a preventative maintenance checks on my own time?

AES resources available in our knowledgebase for questions regarding FAQ's and guides on preventative maintenance. Read our resource on electrical system maintenance and refrigeration maintenance.