Common Maintenance to Perform on Your Salt Spray Chambers

It’s good practice to change your vehicle’s oil every 5,000 miles or so and rotate its tires regularly. If you have larger construction equipment, you know that healthy machinery drives a healthy business.

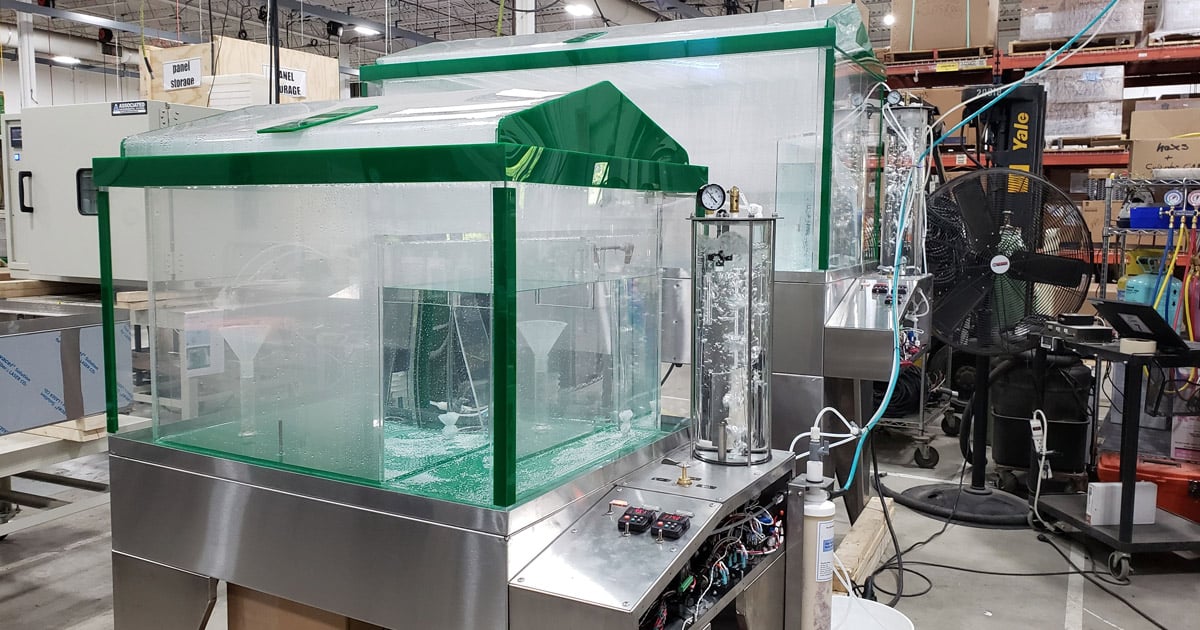

The same is true of test chambers. With salt spray chambers, there’s the added challenge of dealing with corrosive conditions. You need to clean and inspect them after every testing period to prevent small problems from derailing your testing.

It’s important to catch issues early; otherwise, they’ll grow into much bigger and costlier problems.

Maintaining a salt spray chamber includes establishing a service plan with a manufacturer, cleaning it after every testing period, performing maintenance checks quarterly and annually, running your chamber to determine its performance prior to testing, and ensuring all relevant information and manuals remain near your chamber at all times.

Before we consider the routine maintenance you should complete, you should take a few prudent steps first.

Maintenance Precautions to Take

There are several precautions you should take when performing common maintenance on your salt spray chamber:

- Use only parts supplied by the manufacturer of your particular chamber.

- Always connect the chamber to a grounded power supply.

- Always disconnect the chamber from all power sources before servicing.

- Do not expose the chamber to high concentrations of solvents. This could result in crazing of the lucite walls.

- Do not put hot water into the salt reservoir tank for dissolving salt. This could also result in crazing of the lucite walls.

- Observe the recommended temperatures outlined in the operations manual, which should always remain next to your chamber.

Also, proper operation will limit the amount of maintenance you’ll need to conduct. The water supply is particularly important in this regard. Despite being made of corrosion-resistant materials, your salt spray chamber needs filtered water to function correctly (Refer to ASTM B117 for more information regarding water). The mineral content in water varies greatly depending on your location. Depending on your water source, the actual content of the water may consist of impurities such as free chlorine, chlorides, calcium, magnesium, and iron. Impurities in your water supply can be filtered, but the type of filtration system required depends on the concentration and type of impurities. The best way to choose a water filtration system is to have the incoming water supply tested at a local lab. Based on the lab results, select the appropriate filtration system.

Salt spray chambers may also feature demineralizing cartridges to properly filter the water.

Salt Spray Chamber Maintenance

Maintenance isn’t a one-off task designated to certain team members. It’s something that should be practiced by anyone who operates the salt spray chamber by cleaning the chamber after use and keeping an eye out for leaks. Ultimately, failure to frequently run maintenance checks on your salt spray chamber can result in downtimes, delays in product delivery, and lost revenue. Time is money.

Here are more specific things to look for.

Cleaning

Interior

Rinse all internal surfaces with warm water to prevent the build-up of salt after testing. Never use an abrasive material or a solvent, which might damage the acrylic material. Wash away any salt accumulation on the outside of the chamber by repeatedly rinsing with fresh, warm water, and dry all surfaces thoroughly.

Drain Valves

The chamber features three drain valves: one for the saturation tower, one for the salt solution compartment, and one for the test compartment. The test compartment should be drained frequently. Make sure the valves are completely in the closed position to prevent leakage.

Atomizing Nozzle

If the atomizers don’t produce a proper salt fog in the chamber, they may be clogged and should be carefully cleaned. Unscrew the most outside portion of the nozzle, taking care not to drop the spray-tip as it sits loose in the threading. Remove the middle fitting, being careful not to misplace the gasket, then dip the nozzle into clean, warm water and gently shake. This should dissolve any salt deposits and free the nozzle passage.

Calibration

Digital sensors and controllers allow for more accuracy during testing and require special equipment to adjust or calibrate. Calibration should be performed by a trained technician on an annual basis.

On top of maintenance checks, more thorough routine inspections are a must.

If your chambers aren’t working properly, consult your manual for simple fixes. If the problem persists, call AES to find a qualified technician.

The Benefits of Working With the Right Manufacturer

As the adage goes, you get what you pay for. For salt spray chambers, you’re investing not only in the chamber itself but also in the manufacturer. Choosing the right one will help you maintain your chambers for years on end.

A premier chamber manufacturer will expertly walk you through all possible solutions relevant to your environmental testing situation, and remain attentive to your budget constraints. They’ll inform you when you need to update or replace your chamber, or purchase replacement parts.

Reputable manufacturers will provide flexible maintenance plans to accommodate your scheduling and testing requirements. Furthermore, they will make available to you on-site repair service, conduct routine inspections, and even recalibrate instrumentation when necessary.

Testing chamber downtime, delays, or operational setbacks can really undermine your ability to generate profit and serve your customers. A leading manufacturer understands this and should demonstrate a commitment to rapid response times to your requests. If they aren’t quick to react to your inquiries or concerns early on in the purchasing process, you may want to reconsider working with them. This could foreshadow future neglect, meaning more of your precious testing time could be lost.

Alternatively, if you collaborate with a well-established and trustworthy manufacturing partner, you can look forward to a salt spray chamber that performs at its best for an extended lifetime, empowering you to move your products and devices-under-testing through the evaluation process as quickly and effectively as possible.

Associated Environmental Systems is an experienced salt spray chamber manufacturer that prioritizes customer service. Our team of engineers and account representatives are eager to help you meet your testing and maintenance requirements, ensuring your salt spray chamber lives up to its fullest potential. Contact us today to learn more about test chamber service plans.