Understanding the Conditions a Battery is Subjected to During Testing

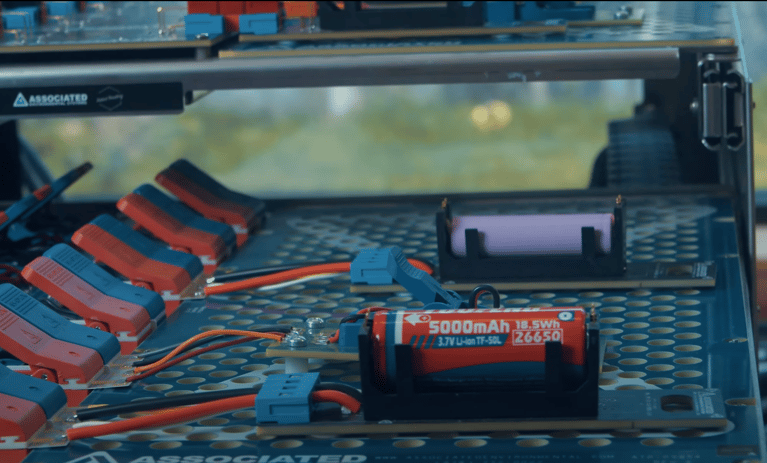

Product development relies heavily on battery testing. Without accurate and appropriate testing, batteries can pose a serious safety hazard. This is a risk not only to the consumer but to the brand itself. At Associated Environmental Systems (AES), we help provide battery test chambers to industries, from automotive, aerospace, energy storage, consumer electronics, and more, to allow companies to catch failures before they are brought to market.

During the testing process, batteries are subjected to several various conditions to ensure reliability, safety, and performance. Different types of stress tests are chosen depending on the regulations and requirements brands are expected to comply with. These factors could include charge/discharge rates, environmental conditions, cycle counts, mechanical constraints, max/min voltage levels, and more. Before you purchase your next test chamber, learn more about a few of these conditions and when they might be essential for testing.

Read Our Battery Chambers Buyers Guide!

Battery Testing

Understanding the rate at which a battery cell charges and discharges is essential. It is an indispensable part of battery testing and can quickly determine how a battery reacts in different temperatures or conditions. Let’s dive into some battery testing methods:

Cell Formation Testing

This final step in cell production is the formation and aging process. During this process, the cell is charged and discharged at a fairly low current of <1C. Its electrodes and electrolytes are activated and stabilized, enabling it to reach full capacity. The results indicate that the battery is reliable and consistent.

For an EV company, this test could be highly beneficial. Since the charge rate influences how quickly an EV can be “refueled,” this test conducted, for example, in a temperature chamber, could determine how to create a battery that can handle higher current densities in high or low temperatures, thus improving the battery’s internal resistance.

Cycling Testing

Gain critical insights into a battery’s longevity and durability through cycling testing. This test identifies a battery’s ability to endure repeated charge and discharge cycles under specific conditions, including temperature and load until battery performance degrades significantly.

A consumer electronics company, for example, could greatly benefit from cycling testing. Not only will it determine the battery life of a device, but it can help provide strategies to maximize battery life and maintain efficiency. Engineers can then determine how to design and structure a battery that won’t accelerate battery degradation.

Capacity Testing

It’s important to measure a battery's ability to store and deliver energy. These can be quantified in amperes or watts. Within this test, a battery is discharged to a specific level, and the energy provided over a period of time is measured. The results indicate the performance of the battery and its energy storage capabilities.

For an energy storage company, capacity testing is vital. This form of testing could help engineers understand how to achieve high levels of renewable energy and optimize the use of renewables. As the demand for energy increases, capacity testing could shape the future of batteries that provide power for longer durations.

Environmental Conditions

In order to effectively conduct battery testing, products must be subjected to environmental conditions. Exposing batteries to various elements such as high/low temperature and humidity allows industries to fully understand the battery’s energy consumption, performance, and optimal range.

AES offers a wide range of environmental battery test chambers. An aerospace company, for example, may approach AES with the need for a chamber that can accurately determine a battery’s performance in extreme cold. A temperature-only chamber such as the Super 508, the most powerful temperature-only benchtop chamber with a range of -37°C to 180°C (-34.6°F to 356°F) could be beneficial for the customer. This chamber also has the capability to be stacked for diverse testing while maximizing lab space. One chamber could be running at extremely cold temperatures while the other is operating at ambient conditions. This can identify potential issues and weaknesses within the battery before it goes to market.

Email Us Today to Learn More About Battery Testing

Mechanical Restraints During Battery Testing

In recent years, mechanical constraint conditions have been popular to subject a battery to during testing. They have the ability to effectively and reliably provide information about the internal state of batteries. The mechanical parameters of a battery are explored through factors such as expansion, strain and force, and ultrasonic probing. Testing these constraints allows engineers to determine the mechanical values of a battery and fix defects.

For an EV company, understanding the mechanical constraints of a battery is imperative for future product development. They have the opportunity to discover changes in volume that are caused by mechanical constraints of inactive materials that strain battery materials. Identifying these materials could avoid battery fracturing, deformation, and more.

Turn to AES for Your Battery Testing Needs

For your next chamber purchase, consider partnering with AES. We purposely and meticulously design each chamber to meet your testing requirements. Our battery test chambers from the temperature-only benchtop SC/SD SAFE series to the benchtop temperature and humidity SCH/BHD SAFE temperature-only and temperature and humidity series find your ideal chamber. Experience unparalleled service and support at each step of the process. Request a quote today!