Humidity Chambers: Calculating Dew Point to Fit Your Testing

Dew point can be a confusing concept when it comes to humidity testing. This is because the relative humidity (RH) within a testing chamber is determined by a specific temperature rather than remaining constant.

For instance, the quantity of moisture in the air at 125 degrees Fahrenheit and 25% RH is different at 75 degrees Fahrenheit and 25% RH. Since warmer air holds higher amounts of humidity, the RH has to be adjusted accordingly to meet testing standards.

In humidity testing, this requires exacting precision, including calculating which dew point is most appropriate for a given temperature and humidity test.

Here’s what you need to know about humidity chambers and how dew point helps you understand their performance limits.

How Test Chambers Create Humidity Conditions

Related to the concept of dew point, RH refers to the level of humidity possible at a particular temperature. For instance, RH at 12 degrees Celsius is quite different from RH at 27 degrees Celsius. That’s why the temperature and humidity levels must work in concert to achieve your desired RH.

Humidity test chambers create and control these conditions accurately, measured by electric sensors. Modern test chambers feature vapor generator systems, closed stainless steel or copper tubes with constant water sources. A heating element in the system creates vapor or steam, which then moves to the plenum to mix with the conditioned air before moving into the workspace. Multiple generators can be employed and synced up for larger workspaces.

These humidity chamber systems have replaced older methods, such as submerging heaters in water pans or utilizing atomizing nozzles (like those still used in salt spray chambers). It’s typical for a humidity chamber to accommodate an RH range between 20% and 95%.

What Is Dew Point?

Chamber manufacturers utilize dew point to identify the RH limitation during testing. Dew point is the temperature at which air must be cooled for it to condense or become wet. In other words, as air temperature increases, so does its capacity to carry water, and when air temperature decreases enough, airborne water particles condense into water droplets known as dew.

For humidity testing purposes, dew point analysis assumes air pressure and water content remain constant while only the air temperature changes.

So, as a formula credited to Mark G. Lawrence, dew point might look something like this, where Dp = dew point temperature, T = temperature observed, and RH = relative humidity.

Dp = T - ((100 - RH)/5)

Calculating Dew Point for Chambers

The dew point is important to humidity testing because it helps you understand, and plan for, the limits of your chamber. Exceeding these limits can cause lasting damage to the chamber.

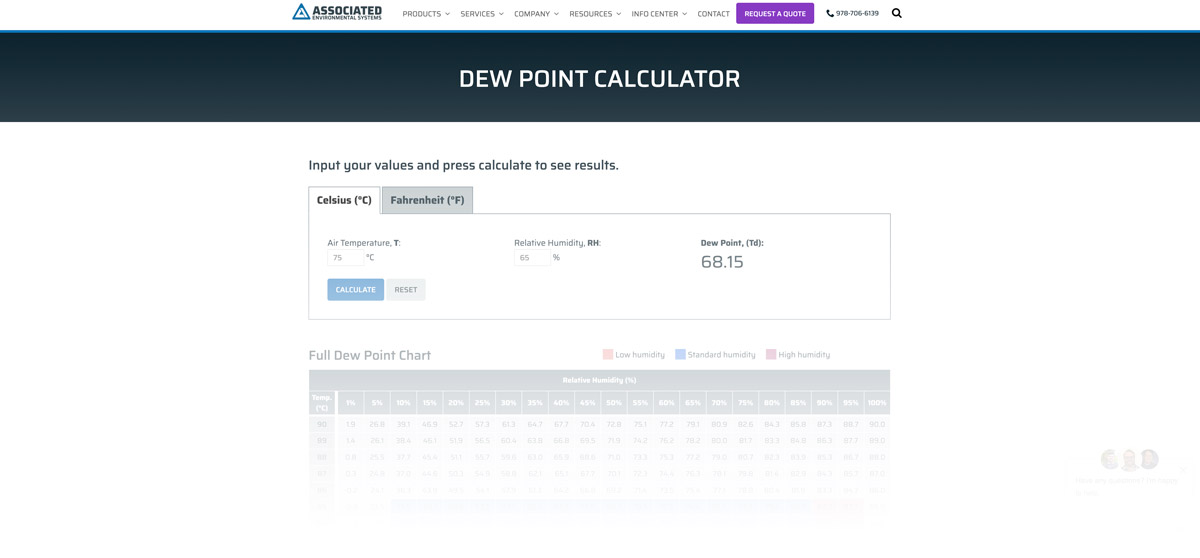

AES developed this dew point calculator and chart to help you plan accordingly. You can adjust temperature and RH settings to gauge what conditions are possible. The blue area represents the standard range of a humidity chamber, with the darker colors signifying extremes.

Now, if you need to reach those extreme levels, you can add features to your chamber. High-humidity sensors enable you to measure humidity as high as 98% RH.

On the other end of the spectrum, humidity levels can reach below 20% RH with the assistance of one of three elements:

-

Nitrogen purge: Since nitrogen is inherently dry, gradually injecting it into the workspace can push out the water-laden air. Additionally, nitrogen can prevent the oxidation of metals and minimize frost accumulation on the surface of devices under testing.

-

Dry-Air Purge Through Desiccant Air Dryer: Before being introduced into the workspace, external compressed air passes through a desiccant system that absorbs moisture, removing excess humidity.

-

Recirculating Desiccant Air Dryer: Chamber size is an essential factor when working with humidity because dry-air or nitrogen purges may not work well with larger workspaces. In these cases, lower humidity levels are achieved by circulating chamber air through a desiccant air dryer before returning it. The moist air is then captured and pushed out to the external workspace.

Relative humidity is an important part of the conversation when purchasing a test chamber. When consulting an experienced manufacturer, you must understand your testing requirements so they can help you find the best chamber that fits your needs.

In summary:

- The amount of moisture in the air changes depending on temperature, understood as a percent (relative humidity).

- In order to guarantee testing conditions can be accommodated by your humidity chamber, you must calculate the dew point.

- Calculating dew point ensures testing results are consistent and reliable (and help the chamber last much longer, as well).