Temperature Chambers and the Future of 3-D-Printed Organs

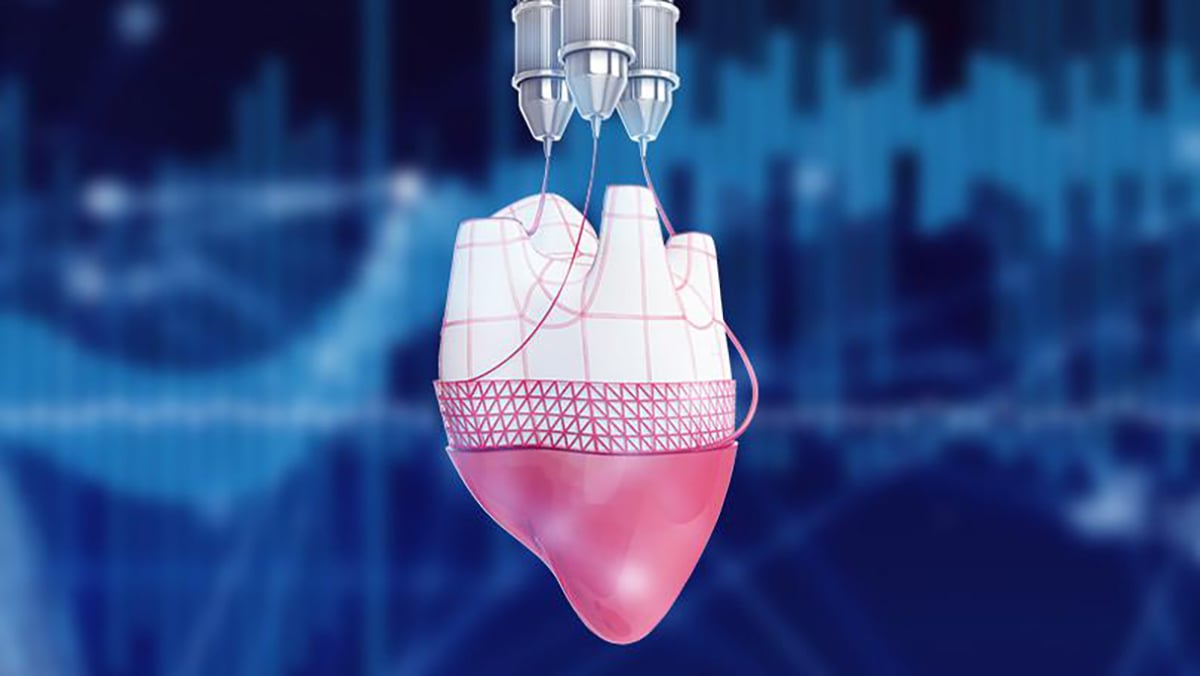

Researchers at UC Berkeley have published a paper in the Journal of Medical Devices which details a new method for bioprinting. Bioprinting is the process of 3-D printing living tissue, bone, blood vessels or even entire organs. It is extremely difficult to accomplish because living cells require very specific environmental conditions to survive and the cells quickly deteriorate if those conditions are not maintained during the printing and subsequent transportation process.

Mechanical engineering professor Boris Rubinsky, a leading researcher on this project and co-author of the paper explains, “Right now, bioprinting is primarily used to create a small volume of tissue. The problem with 3D bioprinting is that it is a very slow process, so you can't print anything big because the biological materials will deteriorate by the time you finish. One of our innovations is that we freeze the material as it is being printed, so that the biological material is preserved, and we can control the freezing rate.”

The UC Berkeley team was able to reduce printing time and speed up production time by using multiple 2D printers to print several tissue layers at once. The multiple 2D layers are then transferred to a different station where they are stacked and assembled into a 3D object made of living tissue. As the 3D object is assembled it is instantly frozen via a quick cryogenic bath. This freezing process helps preserve the tissue and fuse the object together while simultaneously preparing the object for storage and transportation.

Hopefully someday soon this method, or one similar to it, can be developed at scale and used to help improve or even save lives. If that does happen, it seems that there will be a need for storage facilities with precise temperature control - perhaps our walk-in style cold rooms could provide a solution for that requirement. Or, maybe we can help to create an entire temperature controlled environment for the bioprinter devices or QA test the printers themselves in one of our environmental test chambers. In any event, this is a pretty interesting achievement in medical device technology.