Environmental Test Chambers for the Packaging Industry

how environmental test chambers are used in the packaging industry

Unpacking success by testing the limits of packaging durability.

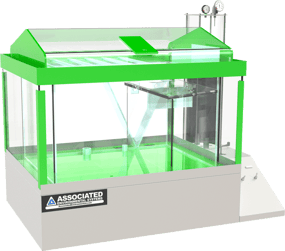

Packaging designers and manufacturers rely on AES environmental test chambers to assess the durability of their materials under various conditions. Chambers simulate different temperature ranges and moisture levels to ensure packaging can withstand real-world environmental challenges.

The primary goal of packaging is to securely contain its contents, preventing leakage, breakage, and other forms of damage. Packaging materials include paper and board (such as paper bags and cartons), rigid plastics, metal, plastic films, and polythene. Each material faces unique stressors, making comprehensive testing essential to guarantee product safety and integrity.

Packaging is utilized across numerous industries, including food, pharmaceuticals, hard goods, soft goods, medical devices, and hazardous materials. Given the diverse applications, packaging standards and regulations vary widely, necessitating specific test requirements tailored to each use case. Environmental test chambers help ensure compliance with these standards, maintaining the highest levels of safety and reliability.

Test Chambers for Packaging: Talk to an Expert

Fill out the form, and you’ll soon be in touch with a test chamber expert.

How Environmental Test Chambers Enhance Packaging R&D for Safe Transit

The packaging industry relies on environmental test chambers to ensure products remain safe and intact during transit. One company purchased an AES walk-in chamber to conduct R&D testing on their packaging. They needed to evaluate how their packaging performed under a wide range of temperatures, simulating conditions experienced during days in transit. Whether testing for food, medicine, or other temperature-sensitive products, the chamber provided the flexibility to replicate various environments. With 80-channel data loggers, the company tracked how each product inside the packaging responded to the conditions. Using AESONE CONNECT, they monitored all test data in real time, gaining valuable insights to optimize their packaging and ensure product reliability.

Environmental Test Chambers for Packages

Temperature Only Chambers

Conduct testing for precise temperature control and uniformity—benchtop, stackable, and walk-in room options.

Workspace Range: 2 to 264 cu ft

Browse Temperature Only Chambers >

Temperature & Humidity Chambers

Conduct temperature and humidity cycling testing. Benchtop, stackable, and walk-in room options

Workspace Range: 2 to 264 cu ft

Browse Temperature & Humidity Chambers >Thermal Shock Chamber

Testing products from one temperature extreme to the other.

Workspace Range: 2 to 264 cu ft

Browse Thermal Shock Chambers >

Salt Spray Chamber

Creates a corrosive environment without introducing other contaminants into the test area.

Workspace Range: 2 to 264 cu ft

Relevant Standards

Clients

-1.png?width=277&height=184&name=SD-508%20(2)-1.png)