Stability Chamber Solutions

Long-term stability testing with stable temperature and humidity for repeatable results every time.

Browse LH SeriesEnvironmental Test Chambers For Stability Testing

Stability test chambers are essential for industries that require consistent, long-term testing conditions—such as pharmaceuticals, consumer products, cosmetics, medical devices, biotechnology and more. Stability chambers are designed to maintain tightly controlled temperature and humidity environments over extended periods to evaluate product shelf life, packaging integrity, and regulatory compliance.

Associated Environmental Systems (AES) designs and manufactures high-performance stability chambers that deliver the accuracy, uniformity, and durability your testing demands. Whether you're performing ICH guideline-compliant pharmaceutical stability testing or monitoring cosmetic product degradation over time, our chambers provide the reliable environmental conditions you need. Backed by decades of engineering expertise, AES chambers are trusted for critical R&D, quality assurance, and compliance testing.

What are Stability Chambers?

Stability chambers are a type of climate chamber designed to maintain stable temperature and humidity for long-term, steady-state testing.

Teams use them to evaluate how products and packaging perform during storage, transport, and real-world environmental exposure.

- Support long-term stability testing, not rapid temperature cycling

- Help evaluate shelf life testing, long-term product performance, and safety

- Validate both products and packaging across changing conditions

- Used across cosmetics, food and beverage, electronics, packaging, and the pharmaceutical industry

Features of stability testing chambers

Long-term stability testing depends on environmental chambers that hold temperature and humidity steady over time.

The best stability chambers combine precise control, reliable performance, clear visibility, and support for accelerated shelf life testing and accelerated aging.

Consistent temperature control:

Maintain optimized air flow and stable temperatures throughout extended tests, with control typically held within ±0.5 °C.

Appropriate temperature range:

Support common stability testing conditions, often spanning –20 °C to +94 °C (–4 °F to +201 °F).

Controlled humidity performance:

Operate across a wide humidity range, commonly 20%–95% RH, with options to extend higher or lower as needed.

Reliable cooling systems:

Use self-contained mechanical refrigeration designed for continuous, steady-state operation.

Monitoring and oversight:

Provide remote monitoring and alerts so teams can track conditions and respond quickly to excursions.

LH Series for stability testing

AES has developed its LH series specifically for steady-state testing. Each LH model is designed to maximize usable space while maintaining uniform conditions.

LH-1.5

1.37 Cubic Feet

Temperature Range: -20°C to +94°C (-4°F to +201.2°F).

Humidity Range: 10% to 95% (98% with added option).

Benchtop Model: Optional double stack available

Remote Monitoring: AESONE CONNECT® included with purchase

LH-6

5 Cubic Feet

Temperature Range: -20°C to +94°C (-4°F to +201.2°F).

Humidity Range: 10% to 95% (98% with added option).

Reach-in Model: Floor stand included in purchase

Remote Monitoring: AESONE CONNECT® included with purchase

What is the Price of a Stability Chamber?

Stability chamber pricing typically starts around $18,000 for a standard unit. Final cost depends on chamber size, performance requirements, and configuration.

Factors that affect price include:

- Workspace volume (cu ft) and overall chamber size

- Temperature and humidity control requirements, including tighter tolerances

- Test profiles, such as steady-state versus accelerated shelf life testing

- Optional features, including dry air purges or desiccant air dryers

- Operational considerations, such as energy use and long-term operating costs

To determine the best fit, work directly with a manufacturer who can tailor a stability chamber to your specific testing needs and budget.

Industries That Rely on Stability Test Chambers

Stability chambers play a vital role in product development, regulatory compliance, and long-term performance testing across a wide range of industries. These chambers provide precise control over temperature and humidity to simulate real-world storage and use conditions—helping manufacturers ensure consistency, safety, and reliability over time.

Explore how stability testing supports critical industries:

-

Pharmaceuticals: Conduct ICH stability testing to ensure product integrity, potency, and shelf life under tightly controlled conditions.

-

Medical Devices: Validate the performance and durability of medical devices in various environmental conditions, from packaging to real-world storage.

-

Consumer Goods: Assess packaging durability, product stability, and shelf life in fluctuating temperature and humidity environments including cosmetics, personal care items and everyday items.

- Biotech & Life Sciences: Maintain consistent environmental conditions for sensitive materials and ensure compliance with global regulatory standards.

Want to learn how stability chambers can support your specific application? Explore the industries we serve and discover how our solutions align with your testing goals.

Controlling Relative Humidity

AES uses vapor generator systems to give you precise control over the humidity conditions of your chambers’ internal workspaces. The vapor generator system is a closed stainless steel or copper tube. An element heats a constant water source creating vapor or steam that travels through the tube and mixes with conditioned air in a plenum before moving into the workspace. Notably, this water source must be treated and demineralized to avoid contaminating the test.

This system yields a standard relative humidity (RH) range between 10% and 98%.

Optional Features to Increase Humidity Range

High Humidity Sensors let you measure humidity as high as 98% RH.

Dry Air Purge Through Desiccant Air Dryers can achieve humidity as low as 5% RH. It compresses air through a desiccant system, absorbing the moisture before it moves into the workspace.

Dry Nitrogen Purges prevent condensation and frost from accumulating on DUT surfaces at colder temperatures by forcing out the moisture-heavy air. This also prevents the oxidation of metals at high temperatures.

Recirculating Desiccant Air Dryers are a more feasible option for larger chambers. Air is circulated through a desiccant system and then returned to the chamber, often cycled through a honeycomb wheel that releases captured moisture into the external workspace.

Associated Environmental Systems has developed a Dew Point Calculator to help you determine whether you'll need optional features for your humidity systems.

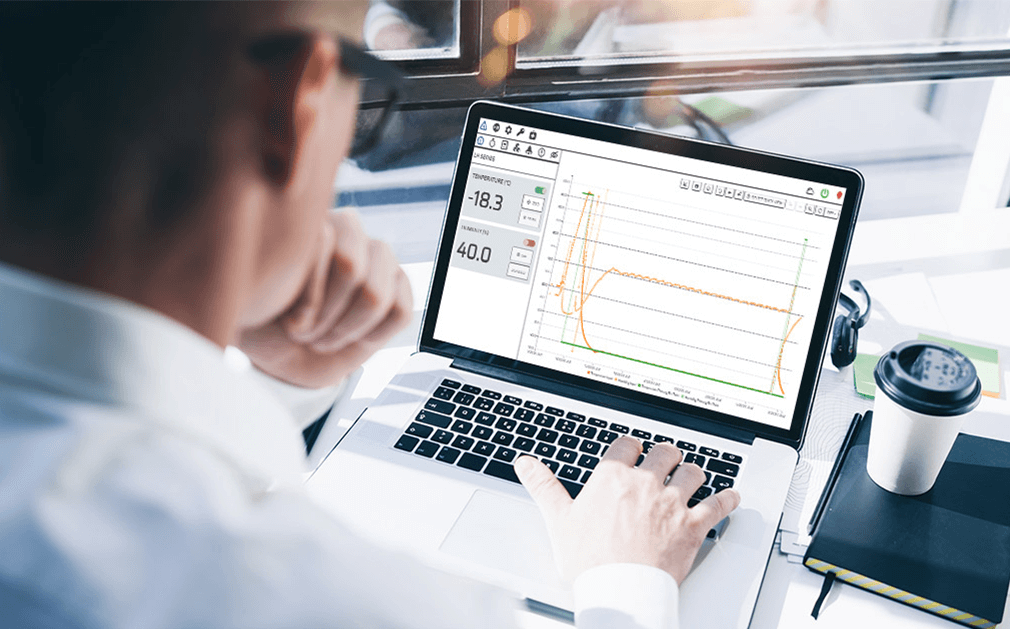

Remote Monitoring With AESONE CONNECT®

An integrated control system allows users to set temperatures, monitor conditions, and respond to immediate alerts.

Our LH Series come standard with AESONE CONNECT®, allowing you to monitor and manage tests remotely. Access real-time and historical data, start or stop test profiles, and adjust settings—all from any web browser.

AESONE CONNECT® features an intuitive dashboard with interactive graphs, customizable data views, and secure multi-user access with permission controls.

Already have an environmental test chamber? AESONE CONNECT® can be retrofitted to most models, extending its functionality and lifespan well beyond a decade.

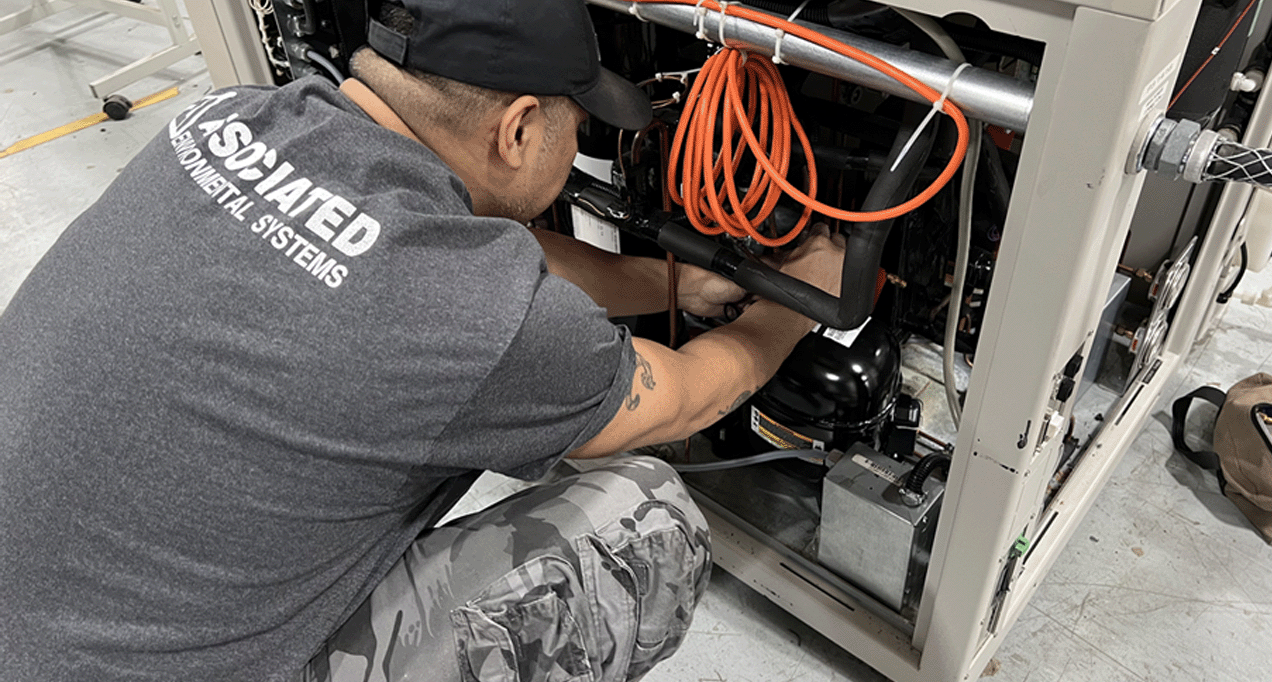

Stability Chamber Maintenance: Why It Matters

Regular maintenance helps stability chambers operate reliably over long service lives, especially systems with humidity control.

Why maintenance matters:

- Supports consistent temperature and humidity performance

- Protects humidity systems through proper water conditioning

- Reduces corrosion, buildup, and performance drift

- Helps prevent unplanned downtime

AES service support:

AES offers nationwide service from experienced technicians, providing preventive maintenance, calibration, troubleshooting, and repairs to keep chambers running as intended.

REQUEST A QUOTE

Frequently Asked Questions

What is a stability chamber?

A stability chamber is a type of environmental test chamber designed to maintain precise temperature and humidity conditions for extended periods. These chambers are used to test how products hold up under long-term storage or transport conditions.

Read More on Stability Chambers

What are stability chambers commonly used for?

Stability chambers are commonly used in pharmaceutical, medical device, cosmetic, and food industries to perform stability testing. They help ensure product safety, shelf life, and regulatory compliance by simulating controlled environmental conditions.

Read more on why LH series are valuable for Industries

What is the purpose of a humidity chamber?

A humidity chamber controls temperature and moisture to evaluate how products and materials perform under humid conditions over time.

Read more on humidity chambers

How much does a stability chamber cost?

Stability chamber costs vary by size, performance range, and configuration. Smaller standard chambers often start in the tens of thousands of dollars, while larger or custom systems cost more.

How do you operate a stability chamber?

To operate a stability chamber, users set the required temperature and humidity, load test samples, and run the chamber continuously while monitoring conditions to ensure stability throughout the test.