Custom Built Liquid Cooled Oven

Industry: Aerospace & Defense

Testing Application: Simulating extreme low-temperature conditions for performance evaluation of defense materials in deep space environments.

The aerospace and defense industries often require rigorous materials and components testing under extreme temperature conditions, particularly those encountered in space. One critical aspect of this testing is evaluating performance at cryogenic temperatures, similar to those found in the vacuum of deep space. For this application, we custom-engineered our standard liquid-cooled oven to reach -150°C (-238°F) to supports these demanding simulations. This level of low-temperature testing is essential for validating the reliability and structural integrity of spacecraft, satellites, and mission-critical components. The ability to precisely replicate deep space thermal conditions allows engineers to predict long-term performance, uncover potential points of failure, and build systems that meet the rigorous demands of aerospace and defense applications.

AES Solution:

To address the critical need for simulating deep space thermal conditions, our solution centered around a custom-engineered Lab oven (ZBD-127), specifically tailored to achieve and maintain a low temperature of -150°C.

- Enhanced Low-Temperature Capability: The chamber's primary customization lies in its ability to reach and stabilize at -150°C, enabling the accurate simulation of deep space thermal environments crucial for evaluating the performance of materials and components intended for such applications.

- Uniform Testing Environment: Five additional temperature sensors strategically placed within the 27 cu. ft. working volume allows for detailed temperature mapping, ensuring a uniform thermal environment for the test articles and accurate data acquisition.

- Direct Product Temperature Monitoring: A dedicated product temperature control sensor provides real-time, direct measurement of the test item's temperature, allowing for precise correlation between the chamber environment and the component's thermal response at -150°C.

- Flexible Configuration: The chamber features two fully adjustable stainless steel shelves, providing versatility in accommodating various sizes and configurations of aerospace and defense components for testing.

- Controlled Thermal Cycling: The system's heat and cool rates of 3 °C/min enable controlled thermal cycling between different temperature points, simulating the temperature variations that components might experience during a deep space mission.

By providing a custom-engineered chamber with advanced low-temperature performance and precise monitoring, we offer a reliable solution for testing materials and components in the extreme conditions of deep space. This allows for accurate performance evaluations, deeper insights into how materials behave at cryogenic temperatures, and greater confidence in developing durable, high-performing technologies for the aerospace and defense industry.

5 product thermocouples and 1 product temperature control sensor

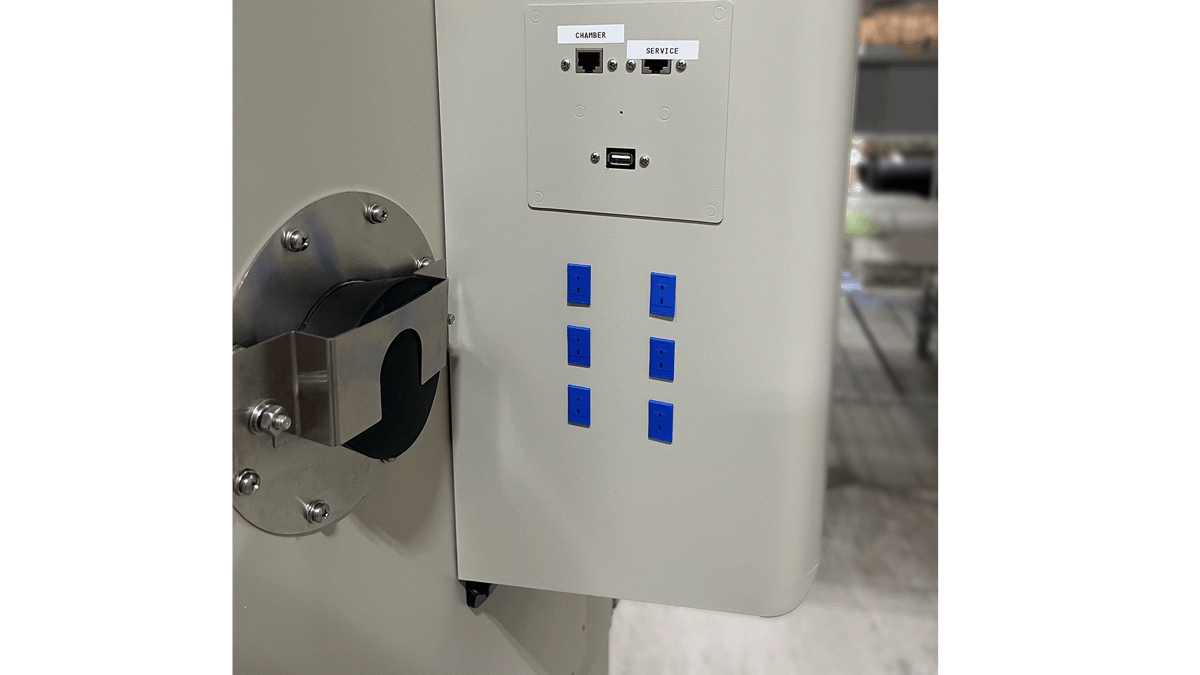

This customer opted for a Watlow F4T controller, limit controller and emergency stop button.