Prevent and Mitigate Battery Events with AES SAFE

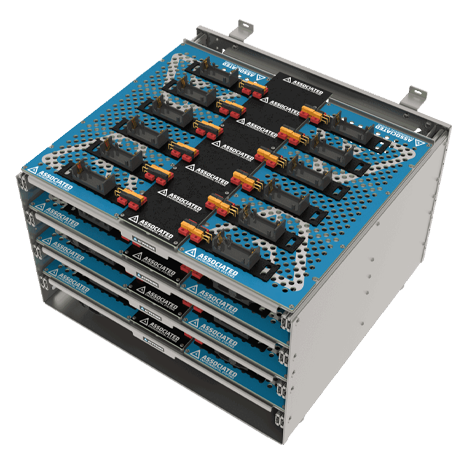

SAFE System

SAFE System — When Safety Isn’t Optional

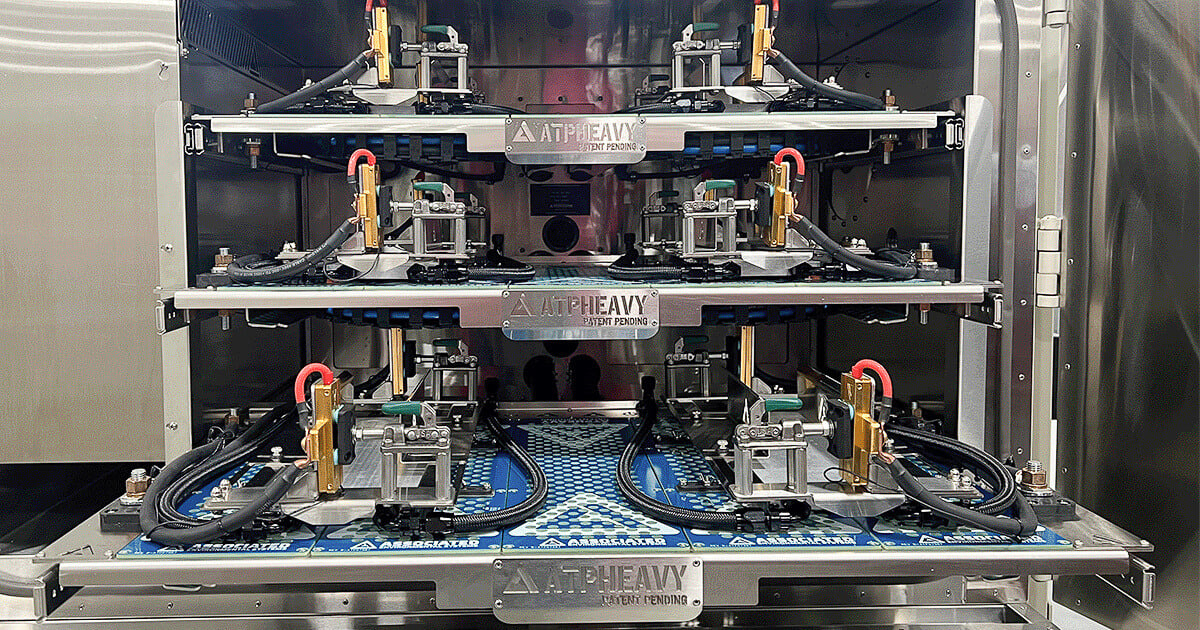

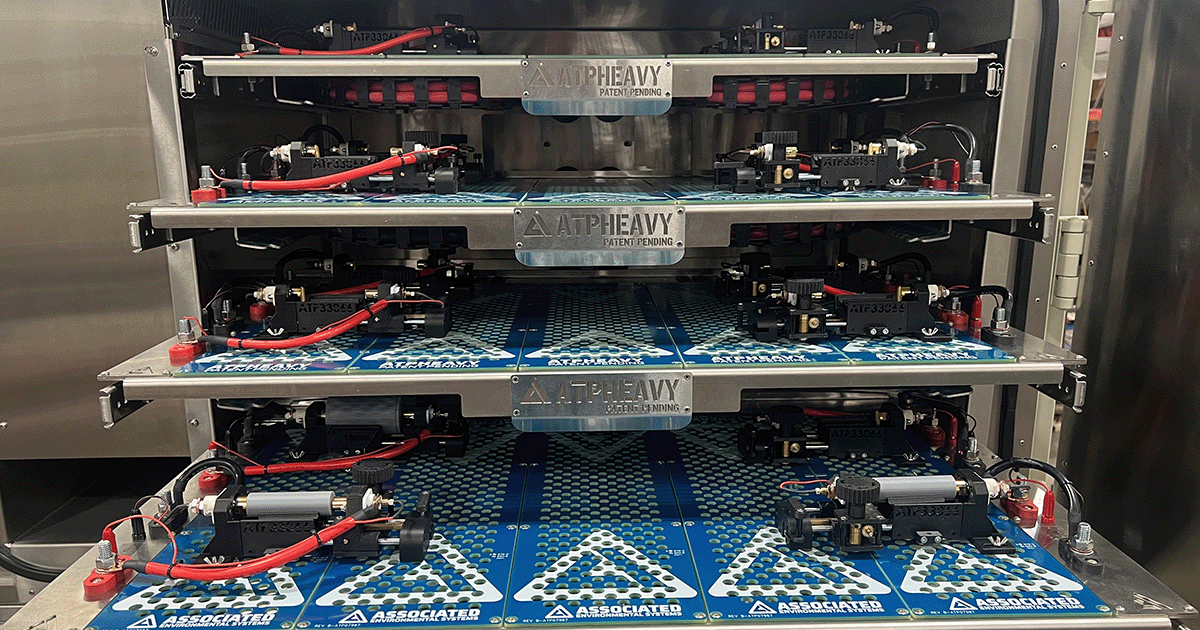

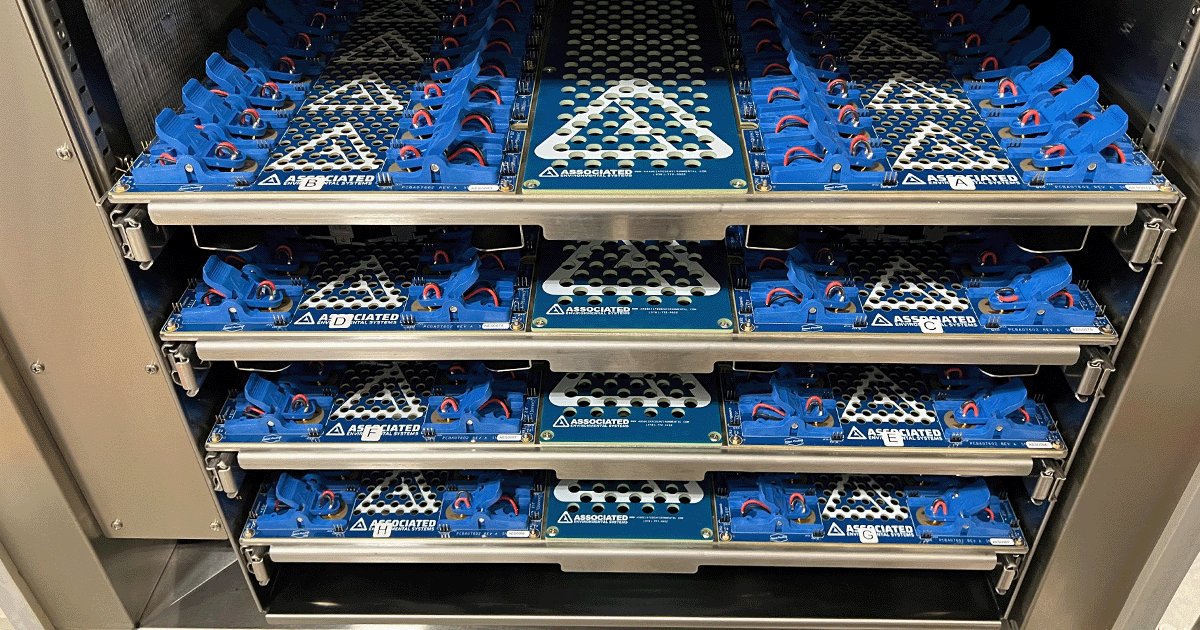

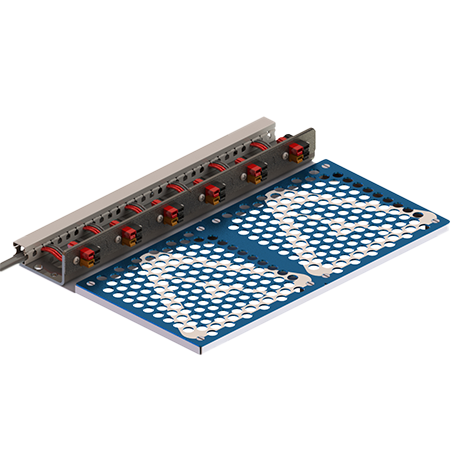

AES’s SAFE System is a purpose-built suite of safety features engineered specifically for battery testing. Unlike general-purpose environmental chambers, the SAFE System is intentionally designed to prevent hazardous battery events before they occur—because when you're testing energy-dense cells, safety isn’t optional, it’s essential.

Built into our chambers from the ground up, the SAFE System incorporates advanced hazard prevention features like temperature-limited sheath heaters to keep heating elements below auto-ignition thresholds, and integrated safety thermocouples that can be placed directly on the battery cell to monitor abnormal temperature rises in real-time. These sensors also allow users to set customizable high-temperature limits for proactive shutoff and alerting.

Additional user-configurable controls include maximum test setpoint limits to avoid test profile errors, and rapid temperature rise detection for early intervention. In the event of a thermal incident, robust mitigation features activate—including atmospheric inertization for fire suppression, a low-flow pressure relief vent to safely exhaust cell gases, and a graphite burst disk for emergency pressure relief.

For more extreme testing conditions, an abuse testing configuration is available, expanding temperature capabilities while maintaining the SAFE System’s core commitment to safety.

.jpg?width=2000&name=WR%201989%20Per2A%20(1).jpg)