Lithium-Ion Battery Testing: Battery Types and Innovations in Test Chambers

Lithium-ion batteries make up some of the most vital technological advancements we have. They power laptops, electrical vehicles, smartphones and other electronic gadgets like UPS systems, portable medical devices, and even the Mars Curiosity Rover.

New research and technological developments require better and more rigorous screening in environmental test chambers before lithium-ion batteries can be determined safe for public use. The results are potentially world-changing: Each innovation opens possibilities for a more sustainable future—and that includes innovations in battery testing.

Common Types of Lithium-ion Batteries

Lithium-ion batteries come in a variety of forms, with different configurations within those forms. They range from the coin cells that power watches, to larger pack batteries that drive electronic transportation. Let’s examine the advantages and disadvantages of each format.

Cylindrical cell batteries, the most common type of lithium-ion battery used today, are made of slab-like anodes (negative or reducing electrodes), cathodes (positive or oxidizing electrodes), and separators rolled up and placed inside a tube-shaped can.

Frequently used in power tools, ebikes, and medical instruments, the primary advantage of cylindrical batteries resides in their shape. Their round form evenly distributes internal pressure, enabling the cells to bear a higher level of pressure without bulging or becoming deformed.

They’ve also powered EVs in a hard pack format. These tend to weigh the vehicles down, however, and the space between each battery reduces the potential energy.

Prismatic cell batteries are similar in makeup to cylindrical cells but are pressed into a cubic shape encased in hard plastic or metal.

As compared to cylindrical batteries, prismatics better utilize space, leaving few if any gaps between them when stacked together or placed inside packs. As one might expect, this tradeoff means thermal management suffers mildly. They can also be more expensive to manufacture and tend to expand with use.

Their applications are found in laptops, smartphones, UPS systems, and support a capacity of less than 20 ampere hours.

Pouch cell batteries innovate on the other two forms by relying on a pliable foil container. This lessens the weight and enables cells to fit more easily into a variety of product spaces. Think of a curved product cavity, for example.

Pouches are designed to tolerate expansion. The smarter designs feature extra space, giving the pouches room to swell as much as 8-10%, which is common after 500 use cycles. One obvious downside to pouch cell batteries is their flexible shell, making them potentially vulnerable to sharp edges or other pointed elements.

Small pouches—those less than 20 ampere hours—are used in handheld electronic devices, laptops, and smartwatches. And while cylindrical and prismatic cells have been employed in electric vehicles (EV), large pouches are driving the future.

These larger, leakproof, laminated bags demonstrate great potential among commercial buses, semi-trucks, marine transportation, and aviation, given they are capable of 100-500 ampere hours.

Shaped like pieces of paper, the large format pouches charge faster, compact more energy, and enable auto manufacturers to further maximize performance.

With the push for more sustainable energy sources, large pouches show plenty of promise. They expand the range of EVs on shorter charges, addressing drivers’ fears of being stranded between recharge stations.

Notably, while lead and nickel are still used in the battery industry, they struggle to compete with the high-energy recharging characteristics of lithium-ion batteries.

Innovations in Test Chambers

The components of lithium-ion batteries can be quite volatile. To guard against thermal incidents, engineers must test them in safe conditions to identify any stress points.

Leading test chamber manufacturers have answered this need with innovations in battery testing solutions. Associated Environmental Systems, for instance, has developed the ATPPRIME series for safe, efficient, and effective battery testing.

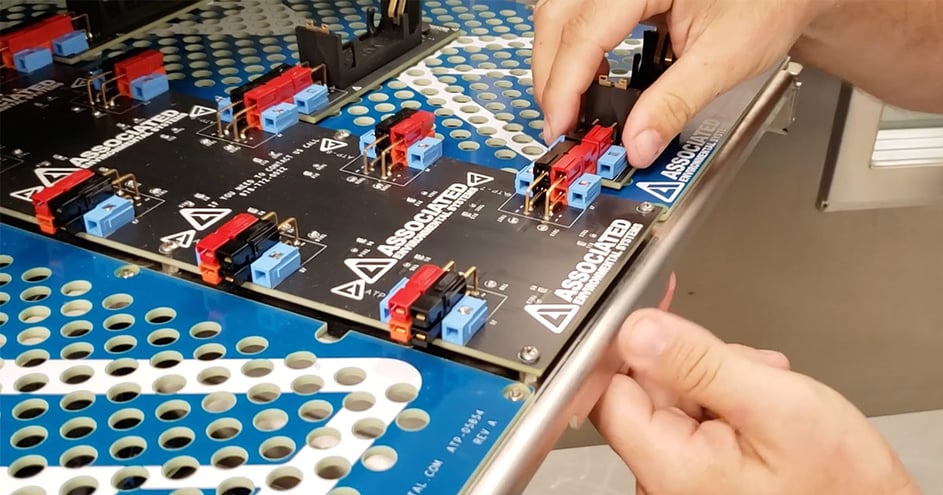

The ATP series can be built to accommodate virtually any cell type (coin, cylindrical, prismatic, pouch, and pack) and customized to meet your exacting requirements. These chambers can hold load sizes of up to 48 different cells across four shelves, and can also be adjusted from one style to another due to their modular fixtures and universal Kelvin connectors.

Now, given the push for sustainable power sources and the promise of large format pouch batteries, AES has introduced ATPPRIME chambers as big as 64 cubic feet in volume to accommodate these batteries.

Here are just a few benefits of AES’s large format test chambers:

- High-current connections and fast change rates

- Clearly labeled components reduce setup time, avoiding disruptions to testing schedules

- Heavy-duty shelves are capable of supporting up to 500 pounds of product

- The built-in Battery Interface Board (BIB) ensures a secure connection and accurate charge and discharge readings and data collection

- Meets test severity requirements with multiple safety features including nitrogen purges, inert gas pressure vents, ventilation blowers, and more

With AES’s test chambers, companies have a reliable and efficient way to test large lithium-ion batteries before they go to market, in a safe, easy-to-use manner.

In addition to being a leader in the test chamber industry, AES offers service plans for the life of their chambers. Its support team can help companies address any maintenance issues for the test chamber and the battery testing fixtures.

The search for more effective batteries is constant. We need them to power our future. You need a test chamber partner like AES to effect real change in this all-important market.