As the original battery testing fixture manufacturer, AES has set the standard for innovation, safety, and reliability in battery testing. Engineered and built in the USA, our fixtures are designed to grow with your testing needs and stand the test of time.

What Is a Battery Test Chamber?

Battery test chambers simulate the most intense real-world conditions your cells are likely to encounter, including extreme temperature fluctuations, humidity levels, and cycling processes. These chambers enable precise testing of battery performance, safety, and reliability by allowing controlled charging and discharging cycles in a controlled environment.

Find the Battery Chamber That’s Right for You

AES fills a key industry gap by providing patented integration of chambers and battery testing equipment, giving customers a single-source solution. This approach streamlines operations, saving both time and money.

Our extensive experience also ensures a smooth installation that minimizes delays and costly mistakes. Backed by hundreds of thousands of active battery test channels, we’ve built a proven track record in the field.

Choose AES for chambers and fixtures that deliver convenience, reliability, and long-term productivity.

Choose Your Battery Test Chamber

The Original Battery Test Chamber, Engineered by AESAES is the original manufacturer of battery test chambers, setting the standard for safe, reliable, and precise testing environments. Our lineup supports every stage of development:

- R&D to production – chambers sized for any cell count or energy capacity

- Flexible testing – from charge/discharge cycles to abuse testing

- Proven design – optimized airflow, tight environmental control, and built-in safety

Test with confidence knowing every AES chamber is purpose-built for battery innovation.

SD-501-3RS

SD-508-SAFE

SC/SCH SAFE Series

FD Safe Series

Large-format chambers in 27 or 48 cu ft.

- Built for extreme testing conditions

- Handles large cells and demanding applications

- Combines space, safety, and durability for long-term reliability

LARGE SCALE BATTERY TESTING

Walk-IN BATTERY TEST CHAMBERS

When testing goes beyond standard chamber sizes, AES provides fully customized walk-in chambers built for large-scale batteries like EV packs, modules, and other high-capacity formats.

Key advantages include:

- Flexible configurations tailored to your specifications

- Advanced safety systems for high-energy testing

- Cycler integration to support efficient, data-driven results

With AES walk-in solutions, you can test efficiently, safely, and at scale.

Building a Battery Testing Lab or Planning an Expansion?

AES helps companies build environments that work today and adapt for tomorrow.

We provide guidance on:

- Power and installation – ensure the lab has the right electrical capacity and infrastructure

- Layout and spacing – optimize chamber placement for performance and safe employee movement

- HVAC and safety systems – maintain stable conditions and meet safety standards

- Training and planning – prepare teams for safe operation and allow room for future growth

| Severity Level | Description | Severity Classification & Effects Criteria |

|---|---|---|

| 0 | No Effect | No effect. No loss of functionality. |

| 1 | Reversible Loss of Function | No defect; no leakage; no venting, fire, or flame; no rupture; no explosion; no exothermic reaction or thermal runaway. Cell reversibly damaged. Repair of protection device needed. |

| 2 | Irreversible Defect/Damage | No leakage; no venting, fire, or flame; no rupture; no explosion; no exothermic reaction or thermal runaway. Cell irreversibly damaged. Repair needed. |

| 3 | Leakage Δ mass <50% |

No venting, fire, or flame; no rupture; no explosion. Weight loss <50% of electrolyte weight (electrolyte = solvent + salt). |

| 4 | Venting Δ mass >=50% |

No fire or flame; no rupture; no explosion. Weight loss ≥50% of electrolyte weight (electrolyte = solvent + salt). |

| 5 | Fire or Flame | No rupture; no explosion (i.e., no flying parts). |

| 6 | Rupture | No explosion, but flying parts of the active mass. |

| 7 | Explosion | Explosion (i.e., disintegration of the cell) |

*Gas Sensors and Additional Safety Features Available

RELATED PRODUCTS

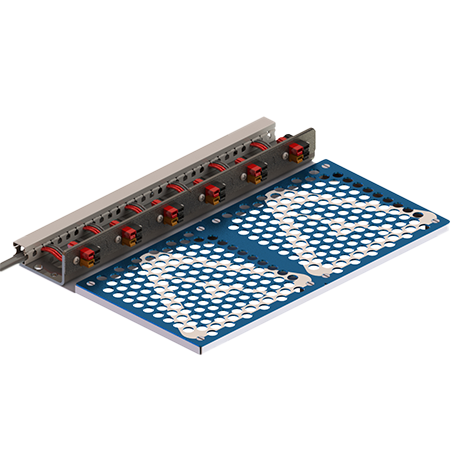

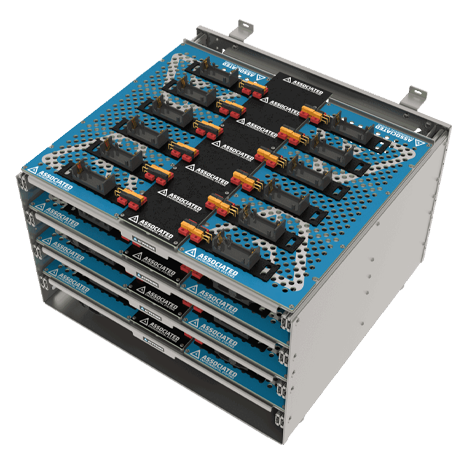

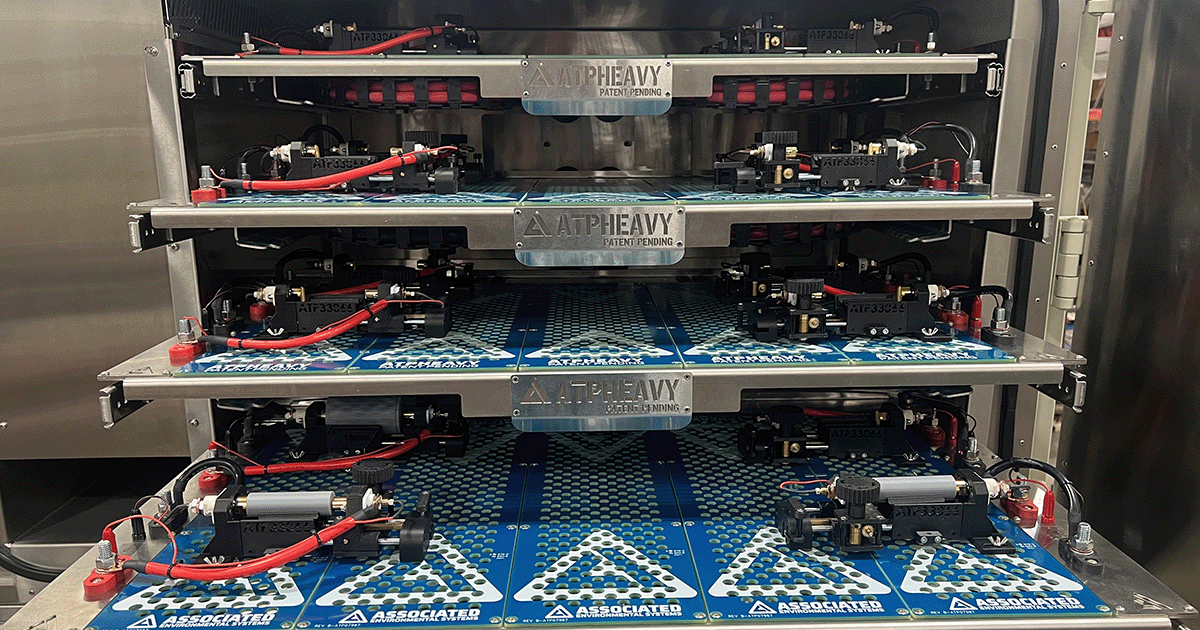

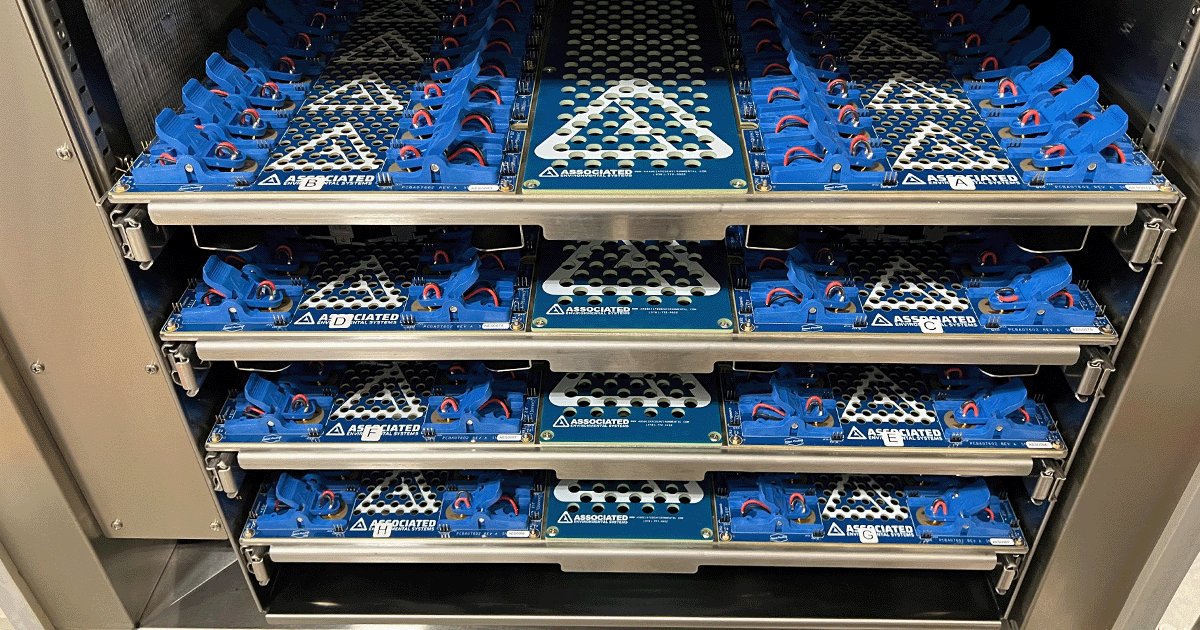

ATP/Cycler Interface Panel

Our cycler interface panel, situated at the rear of the chamber, offers a secure location for connections and ensures safety and functionality for direct communication about the health of your cell.

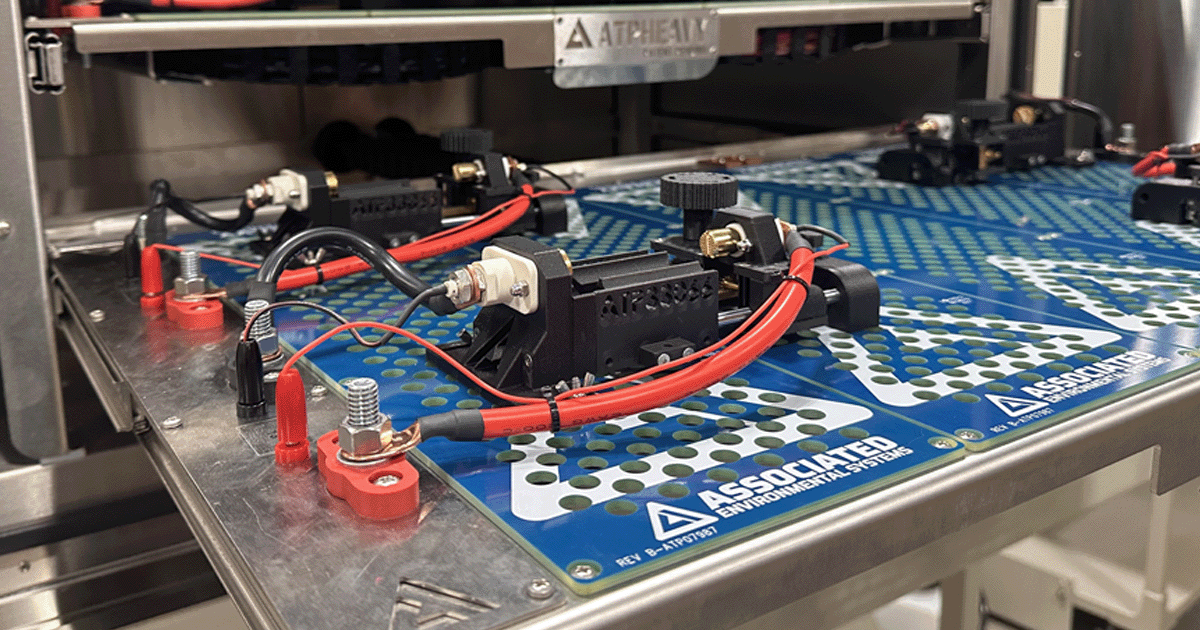

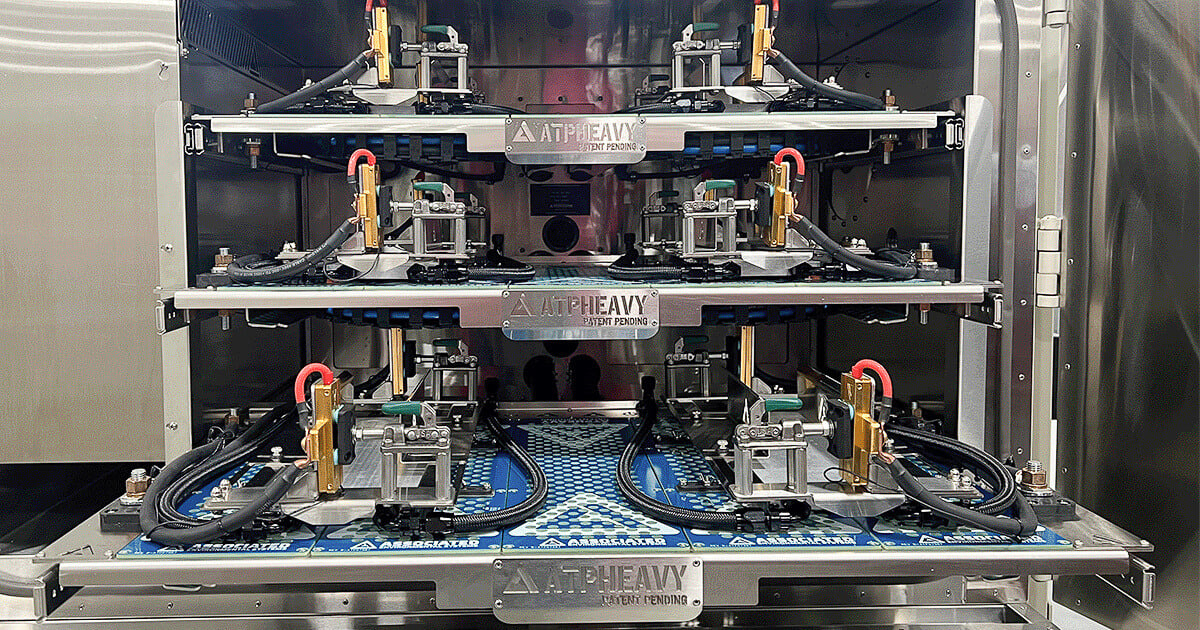

PICTURED: ATPHEAVY CASSETTE

Powering Progress, One Project at a Time

Behind every AES battery test chamber is a story of innovation, precision, and reliability. Our product spotlights highlight real-world applications where our chambers help push battery technology forward—whether it’s enhancing safety, increasing capacity, or supporting groundbreaking research.

See how AES partners with industry leaders to solve complex testing challenges and deliver dependable results.

5000+

Active Battery Test Chambers

200,000+

Active channels deployed in our ATP® systems

up to 1200 Amps

Our ATP® solutions can accommodate less than 1 amp up to 1200 amps continuous or pulse

PREVENT AND MITIGATE BATTERY EVENTS WITH AES SAFE

SAFE SYSTEM - WHY SAFETY ISN'T OPTIONAL

AES’s SAFE System is engineered specifically for battery testing, not adapted from general chambers. It prevents hazardous events before they occur and provides robust safeguards when they do.

Key prevention features:

- Temperature-limited sheath heaters – keep heating elements below auto-ignition thresholds

- Cell-mounted safety thermocouples – monitor abnormal temperature rise in real time

- Customizable high-temp shutoffs – automatic alerts and proactive chamber shutdown

Setpoint controls & rapid rise detection – block unsafe test profiles and trigger early intervention

Built-in mitigation tools:

- Atmospheric inertization – suppresses fire with inert gases

- Low-flow pressure relief vent – safely exhausts cell gases

- Graphite burst disk – emergency pressure relief for worst-case events

Optional abuse testing configuration:

Expands temperature capabilities for extreme test profiles while maintaining SAFE protection.

FAQ: Battery Testing Chambers

An environmental chamber for battery testing simulates real-world conditions so researchers and manufacturers can evaluate how batteries perform, stay safe, and last over time. Below are answers to some of the most common questions about these chambers.

What is the purpose of battery testing?

The purpose of battery testing is to measure performance, safety, and reliability under controlled conditions. Testing shows how batteries respond to stress factors like temperature swings, cycling, and environmental exposure.

What is the function of the battery temperature chamber?

A battery test chamber creates a controlled environment to replicate real-world conditions. It precisely manages temperature, humidity, and airflow so batteries can be safely tested for durability and compliance.

What types of batteries can you test in a battery thermal chamber?

Battery test chambers can test nearly all formats, including cylindrical, prismatic, pouch, coin cells, and full battery packs. This flexibility supports R&D through production-scale testing across many industries.

How does a battery test chamber ensure safety during testing?

A battery test chamber ensures safety by using systems that prevent and contain hazards during operation. Features include over-temperature protection, venting, fire suppression, and real-time monitoring of battery conditions.

What temperature range do battery test chambers cover?

Environmental chambers for battery testing typically cover a wide range of temperatures, from –70°C to +180°C. This range lets you simulate extreme environments, ensuring batteries can operate safely in diverse real-world applications.

Are battery test chambers used for electric vehicle (EV) battery testing?

Yes, battery test chambers are commonly used for EV battery testing. They handle large-format cells and packs, enabling manufacturers to validate performance, safety, and lifecycle under automotive conditions.