HM-436 Environmental Test Chamber

HM Series - Temperature with Humidity

HM-436

Floor

The Model HM-436 is a steady-state temperature and humidity test chamber specially designed for hydrogen-maser atomic clocks.

With 34.6 cubic feet of workspace, the HM-436 is designed to generate and control temperature and humidity environments at and above +23°C (+73.4°F) at 35% relative humidity.

The test chamber is designed for minimal maintenance. Run long-term tests at a constant, steady-state temperature and humidity, or cycle testing with well-tuned reliability. It is known for its ability to run unparalleled tight temperature and humidity control.

HM test chambers feature heating systems equipped with open ceramic-core nichrome heaters for reliable and accurate temperature control within ±0.5°C (±1.0°F).

The humidity system is tuned to operate at a constant 35% relative humidity. For humidification, a vapor generator system incorporating stainless steel blower wheels is used to introduce water vapor into the chamber. The system utilizes safeties to de-energize the vapor generator in the event of no water to the generator tank. Dehumidification is accomplished with a mechanical refrigeration system.

The cooling system consists of a self-contained, compact, mechanical, single-stage refrigeration system.

The HM-436 has casters to increase mobility and offer flexibility in your laboratory. Two doors, front and back, open fully into the workspace and includes a removable ramp. Two power outlets are housed inside the workspace. A 3-inch port on the right side is centered in the workspace from top-to-bottom and front-to-back.

The standard instrumentation includes two manual-set digital controllers for independent control of the temperature and humidity.

- Specifications

- Standard Features

- Instrumentation

- Safety Features

Specifications

| Interior: | 33.0W x 37.0D x 49.0H (in) |

| 838.2W x 939.8D x 1244.6H (mm) | |

| Exterior: | 48.0W x 50.0D x 81.0H (in) |

| 1219.2W x 1270D x 2057.4H (mm) | |

| Volume: | 34.62 cubic ft |

| 980.32 liters | |

| Temperature: | 23°C to 25°C (73.4°F to 77°F) |

| Humidity: | 35% RH steady state with load |

| Humidity Fluctuation: | ±5% RH at sensor |

| Electrical Supply: |

208 VAC, 1 PH, 50 HZ

(Optional) 60HZ |

| Full Load Amps: | 12 A |

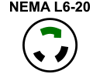

| Facility Power Receptacle: |

NEMA L6-20

|

| Refrigeration System: | Single stage |

| Mobility: | Will fit through 62 in doorway |

| Approximate Product Weight: | 1380.0 lbs (626 kg) without added options |

| Approximate Shipping Weight: | 1490.0 lbs (676 kg) without added options |

Standard Performance

Temperature Only -40° C to +180° C

Temperature & Humidity -40° C to +180° C

| Size | ||

|---|---|---|

| Model | Working Volume | Exterior |

| FD-518 HD-518 | 18.0 cu ft (509.73 l) Interior: 36x24x36 in | 49x60x82 in |

| FD-527 HD-527 | 27.0 cu ft (764.81 l) Interior: 36x36x36 in | 49x72x82 in |

| FD-536 HD-536 | 36.0 cu ft (1,019.46 l) Interior: 36x48x36 in | 49x84x82 in |

| FD-548 HD-548 | 48.0 cu ft (1,358.91 l) Interior: 48x36x48 in | 61x80x94 in |

| FD-564 HD-564 | 64.0 cu ft (22,251.4 l) Interior: 48x48x48 in | 61x92x94 in |

| FD-580 HD-580 | 80.0 cu ft (27,019 l) Interior: 48x60x48 in | 61x104x94 in |

| FD-596 HD-596 | 96.0 cu ft (31,788.5 l) Interior: 48x72x48 in | 61x116x94 in |

Rate of Change Key Thrust: up to 3.9°C/min Impulse: up to 4.0°C/min Warp: up to 6.5°C/min Hyperdrive: up to 9.0°C/min | ||

| 4HP Single Stage Scroll Air-Cooled | 7.5HP Single Stage Scroll Air-Cooled | 12HP Single Stage Scroll or Discus Water-Cooled | 17HP Single Stage Discus Water-Cooled |

|---|---|---|---|

| ↓ 4.5°C/min ↑ 6.0°C/min | ↓ 6.75°C/min ↑ 8.5°C/min | ||

| ↓ 3.75°C/min ↑ 5.5°C/min | ↓ 6.5°C/min ↑ 8.25°C/min | ||

| ↓ 3.0°C/min ↑ 5.0°C/min | ↓ 6.0°C/min ↑ 7.0°C/min | ||

| ↓ 2.5°C/min ↑ 4.75°C/min | ↓ 5.0°C/min ↑ 7.0°C/min | ↓ 6.0°C/min ↑ 7.5°C/min | ↓ 8.0°C/min ↑ 9.0°C/min |

| ↓ 2.0°C/min ↑ 4.0°C/min | ↓ 4.75°C/min ↑ 6.0°C/min | ↓ 5.25°C/min ↑ 6.5°C/min | ↓ 7.5°C/min ↑ 8.0°C/min |

| ↓ 1.5°C/min ↑ 3.5°C/min | ↓ 4.0°C/min ↑ 4.5°C/min | ↓ 4.5°C/min ↑ 5.0°C/min | ↓ 6.5°C/min ↑ 6.5°C/min |

| ↓ 1.5°C/min ↑ 3.5°C/min | ↓ 3.5°C/min ↑ 4.5°C/min | ↓ 4.25°C/min ↑ 5.0°C/min | ↓ 6.0°C/min ↑ 6.5°C/min |

Options: Water-Cooled or Remote Air-Cooled Remote Condensing | Options: Remote Air-Cooled Remote Condensing (Scroll Only) | Options: Remote Air-Cooled | |

*Rise and pull-down rates calculated using IEC 60068-3-5 standard. Custom options available.

*Ideal ambient temperature conditions for test chambers is 23°C (73.4°F). The temperature and humidity range of assured performance is between 15°C and 25°C (59°F/77°F) and 30-50% relative humidity. Conditions outside this range may affect the performance of your test chamber and reduce the lifespan of the equipment.

Notice for Customers Requesting R449A:

Consult our sales team regarding the use of R449A refrigerant (where applicable). This substitution ensures compliance with relevant regulations. Please be aware that the use of R449A will change the achievable low temperature to -35°C. Our sales team can provide detailed information regarding this change for your specific application.

Standard Features

STANDARD FEATURES

- Internal light with external switch

- Forced air circulation

- Standard full opening door, right-hand hinge

- Two 115v, 15a interior outlets

- Full-height battery access door

- Self-contained refrigeration system

- Mechanical dehumidification system

- Steam generator humidity system

- Floor supports 600 lbs

- Live load supported up to 75-100 watts

- Locking swivel casters, set of 4

Instrumentation

STANDARD INSTRUMENTATION

CONTROLLER

2 Independently controlled, manual-set Watlow EZ-ZONE PM controllers for temperature and humidity control (non-programmable)

UPGRADE WITH

HM Series Test Chambers can incorporate AESONE CONNECT creating a robust connected device for a standard and uniform interface making test chamber operation easier.

AESONE XCHANGE increases your functionality

- Connects the test chamber controller to your network for increased accessibility

- On-board multi-year data logging

AESONE SOFTWARE gives you the power to

- Remote chamber operation and monitoring,

- Web-based test profile creation,

- Viewing current data and historical data visually

- Secure multi-level user access

WATLOW F4T PROGRAMMABLE CONTROLLER. Features a 4.3” capacitive touchscreen minimizing the chance for error. Ethernet communication supported by AESONE HARDWARE. View more controller options

ADDITIONAL ONBOARD INSTRUMENTATION

SENSORS.

for temperature, 100 OHM platinum RTD is highly-accurate sensor made from platinum components for increased sensitivity

for humidity, solid-state sensor for 10-95% relative humidity

View sensor options

COMMUNICATIONS. via RS-485

OPTIONAL DATA LOGGERS. View additional data loggers

Safety Features

STANDARD SAFETY FEATURES

- Internal high-temperature limit safety

- Refrigeration system over-pressure safety circuit

- Low-water steam generator over-temperature circuit

Similar Products

Please Try Again.