Environmental Test Chamber

MX Series - Corrosion/Salt Spray

Request a Manual

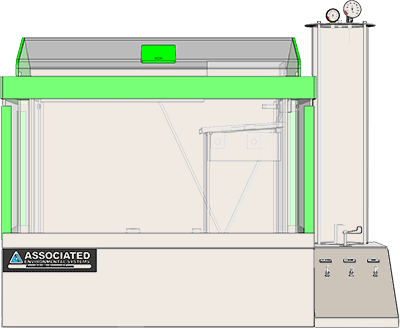

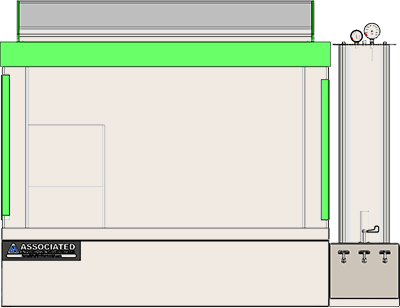

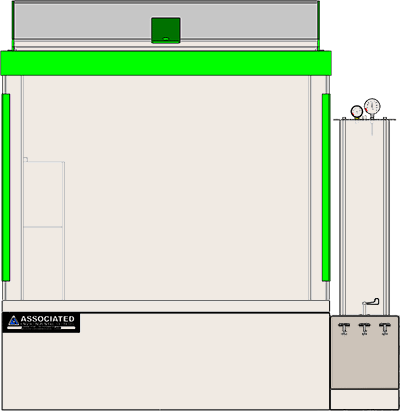

MX-9208

Benchtop

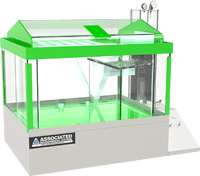

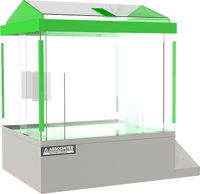

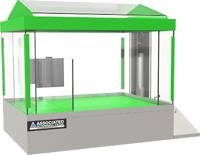

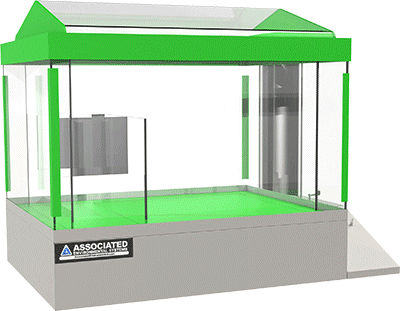

The unique features of the salt spray test chamber, allows you better observation and access to your corrosion testing. The construction is made of high-quality Lucite®️ plexiglass on five sides making it the only 360-degree view into the chamber workspace.

Completely self-contained, the MX Series salt spray chambers allow for test items to be subjected to a corrosive environment without introducing other contaminants into the test area.

STANDARDS. The standard MX-9208 salt spray test chamber has an atomizing nozzle that can be factory set to be compliant with the following standards:

- ASTM-B117

- MIL-STD-202H

- MIL-STD-750F

- MIL-STD-810H

- MIL-STD-883K, with optional modification

- MIL-STD-19500, with optional modification

HEATING SYSTEM. To ensure temperature uniformity in the test workspace, the unit uses two separate RTD sensors. One for holding and conditioning incoming water to an accurate 45.5°C (113.9°F). As the water is mixed with the salt solution and atomized the temperature falls. In the product workspace, a second RTD sensor holds the ambient temperature at a steady 35°C (95°F) as the fog fills the workspace.

Salt Spray chambers are commonly used to evaluate the corrosive properties of:

- Phosphated surfaces (with subsequent paint/primer/lacquer/rust preventive)

- Zinc and Zinc-alloy plating (see also electroplating)

- Electroplated chromium, nickel, copper and tin

- Coatings not applied electrolytically (such as zinc flake coatings)

- Organic Coatings

- Paint Coatings

INSTRUMENTATION. MX-9208 Test Chamber incorporates AESONE CONNECT creating a robust connected device giving you a standard and uniform interface that makes operation easier. Learn more in the Instrumentation Tab below.

- Specifications

- Standard Features

- Instrumentation

- Safety Features

- Optional Features

- Downloads

- Videos

Specifications

MX Series

| Interior: | 24.0W x 24.0D x 24.0H (in) |

| 609.5W x 609.5D x 609.5H (mm) | |

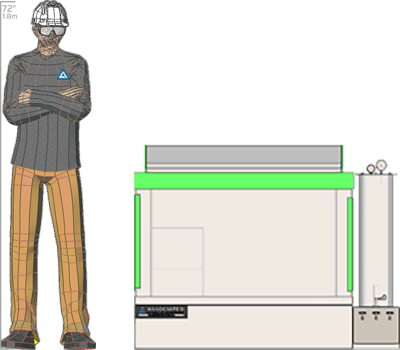

| Exterior: | 39.5W x 42.0D x 38.0H (in) |

| 1003.3W x 1066.8D x 965.2H (mm) | |

| Volume: | 8 cubic ft |

| 226.53 liters | |

| Tower Temperature: | 45.5 °C (114°F) |

| Chamber Temperature: | 35 °C (95 °F) |

| Salt Solution Capacity: | 10.8 gal (41 liters) |

| Saturation Tower Capacity: | 1.9 gal (7.0 liters) |

| Approximate Operating Hours: | 144 hours |

| Compressed Air Requirements: | 30PSI |

| Electrical Supply: | 120 VAC, 1 PH, 60 HZ |

| Full Load Amps: | 8 A |

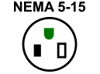

| Power Requirement: |

NEMA 5-15

|

| Mobility: | Will fit through 48 in doorway |

| Approximate Product Weight: | 305.0 lbs (138 kg) without added options |

| Approximate Shipping Weight: | 420.0 lbs (190 kg) without added options |

*Ideal ambient temperature conditions for test chambers is 23°C (73.4°F). The temperature and humidity range of assured performance is between 15°C and 25°C (59°F/77°F) and 30-50% relative humidity. Conditions outside this range may affect the performance of your test chamber and reduce the lifespan of the equipment.

Standard Features

STANDARD FEATURES

- Temperatures

- Tower +45.5°C (+113.9°F)

- Workspace +35°C (+95°F)

- Single tower water conditioning

- Benchtop Style

- Transparent Lucite Construction features visual observation of items being tested

- Stainless steel base

- Tower Level Control

- Salt Spray Reservoir Level control with 10-gallon saltwater storage tank (auto refill system)

- Salt Fog Collectors 80cm Horizontal Area (2 Required) compliant with ASTM-B117

Instrumentation

STANDARD INSTRUMENTATION

CONTROLLER

MX Series Test Chambers have incorporated AESONE CONNECT creating a robust connected device for a standard and uniform interface making test chamber operation easier.

AESONE XCHANGE is hardware internal to the chamber that increases your functionality

- Connects the test chamber controller to your network for increased accessibility

- On-board multi-year data logging

AESONE SOFTWARE gives you the power to

- Remote chamber operation and monitoring,

- Web-based test profile creation,

- Viewing current data and historical data visually

- Secure multi-level user access

ADDITIONAL ONBOARD INSTRUMENTATION

WATLOW F4T PROGRAMMABLE CONTROLLER. Features a 4.3” capacitive touchscreen minimizing the chance for error. Ethernet communication supported by AESONE HARDWARE. View more controller options

SENSORS.

- TEMPERATURE SENSOR. Measured at the point of airflow entering the workspace. Class A, 3-wire, 100 Ohm Platinum RTD sensor

OPTIONAL DATA LOGGERS. View additional data loggers

Safety Features

STANDARD SAFETY FEATURE

Internal thermal heat fuse interrupts electricity flow if it reaches a preset temperature

Optional Features

- Special Filter for MIL-STD-202H and 810H (P/N 86264)

- Modification to Meet MIL-STD-883K Method 1009.8 Procedure 3.1

- Water Demineralizer System

- Floor Stand

Downloads

Videos

Please Try Again.