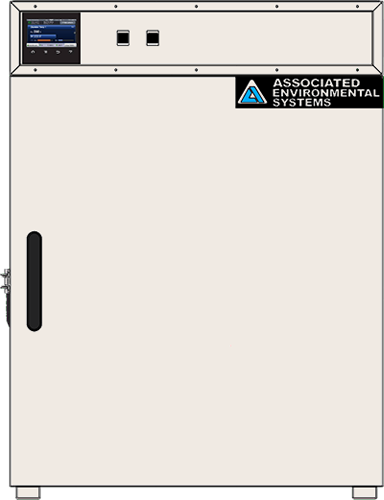

BD-101 Environmental Test Chamber

BD Series - Liquid Cooled Ovens

BD-101

Benchtop

The BD-101 Model is a liquid-cooled laboratory oven capable of providing highly-stable, controlled, forced hot air circulation with rapid cooling using liquid LN2 or CO2.

BD-100 Model Laboratory Ovens provide dry, air-circulated heat as an environmental testing condition. The ability to maintain precise temperatures occur with help from direct, drive-powered fans.

CONSTRUCTION. These liquid-cooled laboratory ovens feature a durable powder-coat finish over heavy-gauge steel, with stainless steel internal construction, and highly-efficient, low K factor, thermal insulation, this is built to last for many years.

CIRCULATION SYSTEM. The performance level operates the internal workspace temperature from approximately -73°C to +220°C (approximately -100.4°F to +428°F).

HEATING SYSTEM. The oven features an industry-leading heating system equipped with low-watt density, ceramic core, nichrome heaters for accurate temperatures within ±0.5°C, as measured at the sensor.

RAPID COOLING. Liquid cooling will bring a hot oven down to ambient conditions and as low as -73°C (-100°F) in just a couple of minutes. Pull-down rates for the liquid cooling process are much faster than traditional test chamber mechanical refrigeration.

BD Series Laboratory Ovens are ideal for:

- aging

- baking

- curing

- drying

- sterilizing

- and more.

If rapid cooling is not a requirement, take a look at the BD-900 Models.

INSTRUMENTATION. The standard BD models have a manual-set digital controller. For more sophisticated test profiles, upgrade incorporates AESONE CONNECT creating a robust connected device giving you a standard and uniform interface that makes operation easier. Learn more in the Instrumentation Tab below.

- Specifications

- Standard Features

- Instrumentation

- Safety Features

- Optional Features

- Downloads

Specifications

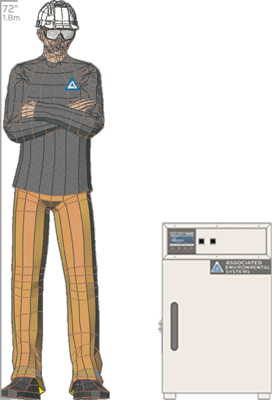

| Interior: | 12W x 11D x 13.3H (in) |

| 304.7W x 279.4D x 337.8H (mm) | |

| Exterior: | 21.6W x 29.9D x 31.1H (in) |

| 548.7W x 759.5D x 790H (mm) | |

| Volume: | 1.02 cubic ft |

| 28.88 liters | |

| Temperature: | -73°C to 220°C (-99.4°F to 428°F) |

| Temperature Stability: | ±0.5°C (±1.0°F) at sensor after stabilization |

| Rise Rate*: | 4.88°C/min |

| Pull Down Rate*: | 9.6°C/min |

| Electrical Supply: | 120 VAC, 1 PH, 50HZ or 60HZ |

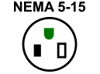

| Facility Power Receptacle: |

6' NEMA 5-15

|

| Full Load Amps: | 14 A |

| Airflow: | 50 CFM |

| Refrigeration System: | Liquid cooled-no mechanical refrigeration |

| Mobility: | Will fit through 36 in doorway |

| Approximate Product Weight: | 140 lbs (63 kg) without added options |

| Approximate Shipping Weight: | 250.0 lbs (113 kg) without added options |

*Rise and pull-down rates calculated using IEC 60068-3-5 standard. Custom options available.

*Ideal ambient temperature conditions for test chambers is 23°C (73.4°F). The temperature and humidity range of assured performance is between 15°C and 25°C (59°F/77°F) and 30-50% relative humidity. Conditions outside this range may affect the performance of your test chamber and reduce the lifespan of the equipment.

Notice for Customers Requesting R449A:

Consult our sales team regarding the use of R449A refrigerant (where applicable). This substitution ensures compliance with relevant regulations. Please be aware that the use of R449A will change the achievable low temperature to -35°C. Our sales team can provide detailed information regarding this change for your specific application.

BD Series

Standard Features

STANDARD FEATURES

- Temperature Range: -73°C to +220°C (-99.4°F to +428°F)

- Exterior cabinet: cold-rolled steel, heavy-gauge, powder coat finish, color: bone

- Interior cabinet: stainless steel, type 304

- Cooling type: LN2 (40 PSI)

- Forced air circulation

- Port configuration: left side port and plug with 2" diameter

- Port configuration: right side port and plug with 2” diameter

- Fully adjustable shelf, 1 wire-grid shelf, stainless steel

- Fully opening door, manual door latch

Instrumentation

STANDARD INSTRUMENTATION

CONTROLLER

Temperature is manually set with one Watlow EZ-ZONE PM controller (non-programmable)

UPGRADE WITH

BD Series Test Chambers can incorporate AESONE CONNECT creating a robust connected device for a standard and uniform interface making test chamber operation easier.

AESONE XCHANGE increases your functionality

- Connects the test chamber controller to your network for increased accessibility

- On-board multi-year data logging

AESONE SOFTWARE gives you the power to

- Remote chamber operation and monitoring,

- Web-based test profile creation,

- Viewing current data and historical data visually

- Secure multi-level user access

WATLOW F4T PROGRAMMABLE CONTROLLER. Features a 4.3” capacitive touchscreen minimizing the chance for error. Ethernet communication supported by AESONE HARDWARE. View more controller options

ADDITIONAL ONBOARD INSTRUMENTATION

SENSORS. 100 OHM Platinum RTD is a highly-accurate sensor made from platinum components for increased sensitivity View sensor optionsSafety Features

STANDARD SAFETY FEATURE

HIGH/LOW TEMPERATURE CONTROL. An adjustable temperature limit controller allows you to program the highest lowest temperature the device under test, protecting products from compromising temperature exposure.

Optional Features

- Shelf Modification

- Custom Porting Sizes

- Cooling Type: CO2 1,000 PSIG (300 PSI available on request)

- CO2 scrubber with replaceable cartridge, for 1,000 PSIG only

- Additional Blank Door

- Desiccant Air Dryer to ensure conditions as low as 5% RH

- Gas Purge compatible with Dry Nitrogen (GN2) & Compressed Dry Air (CDA)

- Floor Stand w/ Casters

Downloads

Please Try Again.