Environmental Test Chamber

FDR Series - Temperature Only

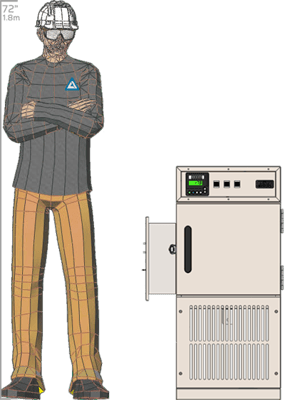

FDR-501

Floor

The FDR-501 test chamber offers the ability to test frequency generating devices within a shielded environment, effectively shielded frequencies from entering inside and from escaping out of the test chamber workspace.

an independent test facility to certify attenuation. Your chamber comes with a test report showing attenuation performance.

Powerful and Consistent Radio Frequency Blocking

- Cellular, metallic, chromatic gaskets and conductive adhesives create a sealed workspace

- RF Honeycomb shielded grill keeps the circulation motor cool

- Electrical wires into the working volume travel through special RF filters

- Standard and Customer requested RF-rated connectors are installed on a side-mounted interface plate providing a shielded pass-through grid for communication with the device under test. (DUT)

- Temperature range -37°C to +94°C (-34.6°F to +201.2°F)

- Wide attenuation range encompassing many products

- Independently certified for accuracy

STRUCTURE. The internal workspace is lined with type 304 stainless steel for a vapor-tight internal construction. The exterior has a durable powder-coat finish over heavy-gauge steel for a long-lasting clean look. Between the two layers is highly-efficient, low k-factor, thermal insulation. This chamber is built to last for many years.

CIRCULATION SYSTEM. Air circulation is crucial for environmental testing. The FDR-501 Test Chamber has a proprietary baffle and fan design combination. This optimizes temperature conditions within the workspace.

HEATING SYSTEM. FDR test chambers feature heating systems equipped with open ceramic-core nichrome heaters for reliable and accurate temperature control within ±0.5°C.

COOLING SYSTEM. The cooling system in the is FDR-501 consists of a self-contained, compact, single-stage, mechanical refrigeration system with an air-cooled condenser. An optional water cooling condenser is available.

Add boost cooling with liquid LN2 or CO2 to shorten pull-down times; it's a great option for stress tests that require rapid cooling.

INSTRUMENTATION. FDR Series Test Chambers have incorporated the AESONE CONNECT creating a robust connected device for a standard and uniform interface making operation easier. Learn more in the Instrumentation Tab below.

- Specifications

- Standard Features

- Instrumentation

- Safety Features

- Optional Features

- Downloads

- Videos

Specifications

FDR Series

| Interior: | 13.5W x 16D x 9H (in) |

| 342.9W x 406.4D x 228.6H (mm) | |

| Exterior: | 25.5W x 32D x 41H (in) |

| 647.7W x 812.8D x 1041.4H (mm) | |

| Volume: | 1.13 cubic ft |

| 31.99 liters | |

| Temperature: | -37°C to 94°C (-34.6°F to 201.2°F) |

| Rise Rate*: | 3.14°C/min |

| Pull Down Rate*: | 1°C/min |

| Electrical Supply: |

120 VAC, 1 PH, 50 HZ

(Optional) 60HZ |

| Full Load Amps: | 20 A |

| Facility Power Receptacle: |

NEMA 5-20

|

| Refrigeration System: | Single stage |

| Mobility: | Will fit through 36 in doorway |

| Approximate Product Weight: | 325 lbs (147 kg) without added options |

| Approximate Shipping Weight: | 435 lbs (197 kg) without added options |

*Rise and pull-down rates calculated using IEC 60068-3-5 standard. Custom options available.

*Ideal ambient temperature conditions for test chambers is 23°C (73.4°F). The temperature and humidity range of assured performance is between 15°C and 25°C (59°F/77°F) and 30-50% relative humidity. Conditions outside this range may affect the performance of your test chamber and reduce the lifespan of the equipment.

Notice for Customers Requesting R449A:

Consult our sales team regarding the use of R449A refrigerant (where applicable). This substitution ensures compliance with relevant regulations. Please be aware that the use of R449A will change the achievable low temperature to -35°C. Our sales team can provide detailed information regarding this change for your specific application.

Standard Features

STANDARD FEATURES

- Temperature range: -40°C to +94°C (-40°F to 201.2°F)

- Reliable and accurate: an independent test facility certified attenuation. Your chamber comes with a test report showing attenuation performance.

- Interior cabinet: stainless steel, type 304

- Exterior cabinet: cold-rolled steel, heavy-gauge, powder coat finish, color: bone

- Internal light with external switch

- Swivel brake casters

- Full opening door, manual door latch, blank (no window)

- Silver-soldered refrigeration plumbing for radio wave leak prevention

- EMI filtering electrical connections and sensors, electrical wires into the working volume travel through special RF shielding filters

- EMI honeycomb mesh shielded grill keeps the circulation motor cool

- Electrically conductive cellular, metallic, chromatic door gasket, and conductive adhesives create a sealed workspace

- Standard and customer requested RF-rated connectors are installed on side-mounted interface plate providing a shielded pass-through grid for communication with device under test. Various input/output connector options such as but not limited to:

- Coax feed through connectors - BNC, SMA, TNC, Type F, Type N, UHF

- RF filtered d-sub connectors - DB9, DB15, DB25, DB37, DB50

- Ethernet connectors - 10-gigabit ethernet filter with POE, RJ45 adapter kit, 10/100/1000/10,000 with or without filtering, with or without auto mode detection

- USB connectors - shielded USB 3.x high-speed interface, USB type C, high-speed USB 2.x EMI filter, USB-S shielded adapter kit, unfiltered shielded USB 2.0/3.0/3.1 A-A I/O connector, USB-AS shielded adapter kit

- Fiber optic connectors - FC simplex fiber bulkhead, ST multimode bulkhead, fiber APC FC bulkhead connector

- Data adapter kits - IEEE 1394, VGA, HDMI, DB9 - RJ11, DB9 - RJ11, PS/2 to DB9

- AC/DC power filters - IEC power entry mode, 4 or 6 pole filtered AC or DC terminal block, banana jacks, 4-5-6 outlet power strips

- If your connector is not listed please talk to a sales team member about your specific requirements.

Instrumentation

STANDARD INSTRUMENTATION

CONTROLLER

FDR Series Test Chambers have incorporated AESONE CONNECT creating a robust connected device for a standard and uniform interface making test chamber operation easier.

AESONE XCHANGE increases your functionality

- Connects the test chamber controller to your network for increased accessibility

- On-board multi-year data logging

AESONE SOFTWARE gives you the power to

- Remote chamber operation and monitoring,

- Web-based test profile creation,

- Viewing current data and historical data visually

- Secure multi-level user access

ADDITIONAL ONBOARD INSTRUMENTATION

WATLOW F4T PROGRAMMABLE CONTROLLER. Features a 4.3” capacitive touchscreen minimizing the chance for error. Ethernet communication supported by AESONE HARDWARE. View more controller options

SENSORS. 100 OHM Platinum RTD is a highly-accurate sensor made from platinum components for increased sensitivity View sensor options

OPTIONAL DATA LOGGERS. View additional data loggers

Safety Features

STANDARD SAFETY FEATURES

- HIGH/LOW TEMPERATURE CONTROL. An adjustable temperature limit controller allows you to program the highest lowest temperature the device under test, protecting products from compromising temperature exposure.

- Internal high-temperature limit safety

- Refrigeration system over-pressure safety circuit

- UL508A certified by TUV Rheinland N.A

Optional Features

- Shelf Modification

- LN2 Boost Coo l

- CO2 Boost Cool

- Custom Port Configuration and Attachments

- Noise Reduction Package

- High/Low-Temperature Safety - manual-control, digital-set temperature safety shuts-down test chamber if it goes over or below a specified temperature

Downloads

Videos

Please Try Again.