Environmental Test Chamber

FD Series - Temperature Only

Request a Manual

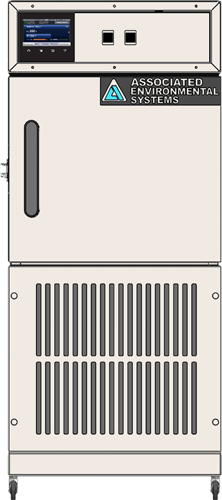

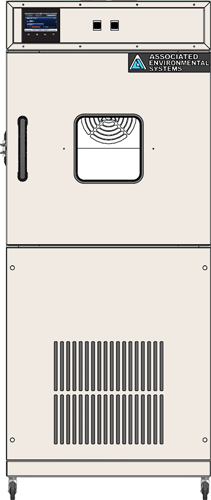

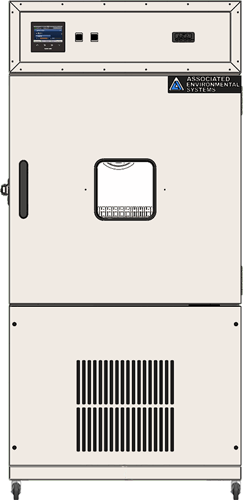

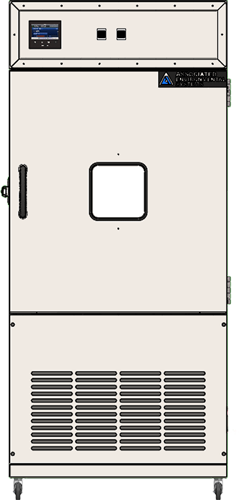

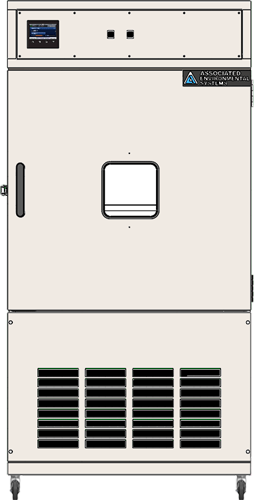

FD-510

Floor

FD-510 Model is a floor-style temperature-only environmental test chamber.

STRUCTURE. The internal workspace is lined with type 304 stainless steel for a vapor-tight internal construction. The exterior has a durable powder-coat finish over heavy-gauge steel for a long-lasting clean look. Between the two layers is highly-efficient, low k-factor, thermal insulation. This chamber is built to last for many years.

CIRCULATION SYSTEM. Air circulation is crucial for environmental testing. The FD-510 Test Chamber has a proprietary baffle and fan design combination. This optimizes temperature conditions within the workspace.

HEATING SYSTEM. FD test chambers feature heating systems equipped with open ceramic-core nichrome heaters for reliable and accurate temperature control within ±0.5°C.

COOLING SYSTEM. The cooling system in the is FD-510 consists of a self-contained, compact, single-stage, mechanical refrigeration system with an air-cooled condenser. An optional water cooling condenser is available.

Add boost cooling with liquid LN2 or CO2 to shorten pull-down times; it's a great option for stress tests that require rapid cooling.

INSTRUMENTATION. FD Series Test Chambers have incorporated the AESONE CONNECT creating a robust connected device for a standard and uniform interface making operation easier. Learn more in the Instrumentation Tab below.

ALTERNATIVE TEMPERATURE RANGES:

- FD-210 -70°C to 180°C (-94°F to 356°F)

- Specifications

- Standard Features

- Instrumentation

- Safety Features

- Optional Features

- Downloads

Specifications

FD Series

| Interior: | 24W x 27D x 28H (in) |

| 609.5W x 685.8D x 711.1H (mm) | |

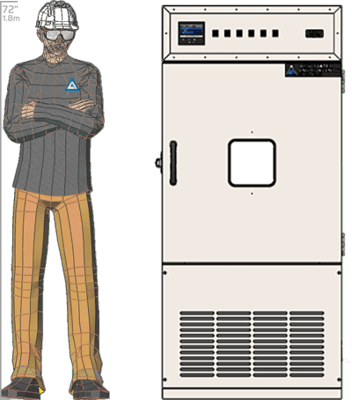

| Exterior: | 33.7W x 46.1D x 74.9H (in) |

| 856W x 1171D x 1902.5H (mm) | |

| Volume: | 10.5 cubic ft |

| 297.32 liters | |

| Temperature: | -37°C to 180°C (-34.6°F to 356°F) |

| Rise Rate*: | 5°C/min |

| Pull Down Rate*: | 4°C/min |

| Electrical Supply: | 208 VAC, 1 PH, 60 HZ |

| Full Load Amps: | 23 A |

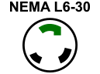

| Power Requirement: |

NEMA L6-30

|

| Refrigeration System: | Single stage |

| Mobility: | Will fit through 48 in doorway |

| Approximate Product Weight: | 590 lbs (268 kg) without added options |

| Approximate Shipping Weight: | 700 lbs (317 kg) without added options |

*Rise and pull-down rates calculated using IEC 60068-3-5 standard. Custom options available.

*Ideal ambient temperature conditions for test chambers is 23°C (73.4°F). The temperature and humidity range of assured performance is between 15°C and 25°C (59°F/77°F) and 30-50% relative humidity. Conditions outside this range may affect the performance of your test chamber and reduce the lifespan of the equipment.

Standard Features

STANDARD FEATURES

- Temperature range: -37°C to 180°C (-34.6°F to +356°F)

- Exterior structure is heavy gauge, cold-rolled steel with powder coat bone color and matte finish

- Interior cabinet: stainless steel, type 304

- Interior light with exterior switch on cabinet face and operable on AESONE CONNECT

- Port configuration: right wall access port and plug with 3in (76.2mm) diameter

- Port configuration: left wall access port and plug with 3in (76.2mm) diameter

- Fully adjustable shelf, 1 wire-grid shelf, stainless steel

- Forced air circulation

- Multipane 12 in x 12 in heated viewing window

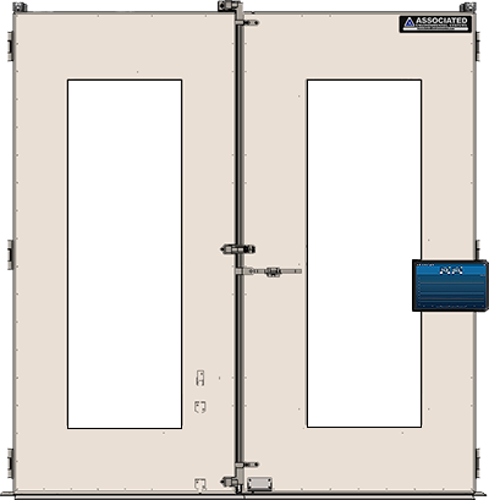

- Full opening door with adjustable manual latch

- Locking Swivel Casters, Set of 4

Instrumentation

STANDARD INSTRUMENTATION

CONTROLLER

FD Series Test Chambers have incorporated AESONE CONNECT creating a robust connected device for a standard and uniform interface making test chamber operation easier.

AESONE XCHANGE is hardware internal to the chamber that increases your functionality

- Connects the test chamber controller to your network for increased accessibility

- On-board multi-year data logging

AESONE SOFTWARE gives you the power to

- Remote chamber operation and monitoring,

- Web-based test profile creation,

- Viewing current data and historical data visually

- Secure multi-level user access

ADDITIONAL ONBOARD INSTRUMENTATION

WATLOW F4T PROGRAMMABLE CONTROLLER. Features a 4.3” capacitive touchscreen minimizing the chance for error. Ethernet communication supported by AESONE HARDWARE. View more controller options

SENSORS.

- TEMPERATURE SENSOR. Measured at the point of airflow entering the workspace. Class A, 3-wire, 100 Ohm Platinum RTD sensor

OPTIONAL DATA LOGGERS. View additional data loggers

Safety Features

STANDARD SAFETY FEATURES

- HIGH/LOW TEMPERATURE CONTROL. An adjustable temperature limit controller allows you to program the highest and lowest temperature of the device under test, protecting products from compromising temperature exposure.

- Over Temperature Heat Fusing

- Refrigeration system over-pressure safety circuit

Optional Features

- Shelf Modification

- Custom Porting Sizes

- Custom window size

- Noise Reduction Package

- LN2 Boost Cool

- CO2 Boost Cool

- Desiccant Air Dryer to ensure conditions as low as 5% RH

- Dry Nitrogen Purge to keep condensation and frost from accumulating on DUT surfaces at cold temperatures and to prevent oxidation of metals surfaces at high temperatures

Downloads

Please Try Again.