Humidity Chambers

High-performance humidity chambers engineered for stability, consistency, and long-term dependability.

Browse ProductsAES Humidity Chambers: Built for Precision, Backed by Experience

Every AES temperature humidity chamber delivers precise control of temperature and humidity in fully enclosed environments. By recreating real-world extremes, these chambers validate product performance, durability, and compliance under demanding conditions.

Backed by decades of expertise, AES offers a full range of temperature and humidity test chambers engineered for accuracy, consistency, and long-term reliability—supporting critical research, development, and regulatory requirements.

Explore AES Humidity Chambers by Series

Temperature and Humidity Chamber Solutions Built for Every Lab and Application

Whether you need a benchtop temp humidity chamber or a full-scale humidity control chamber, AES delivers a reliable solution engineered for consistent environmental performance.

- Multiple formats – benchtop, mid-size, and large-capacity chambers to match your lab space

- Application-ready – support for steady-state, accelerated stress, and long-duration studies

- Custom builds – modify any chamber to fit your specific test requirements

- Integrated workflow – connectivity and monitoring options to streamline operation

AES Humidity Chambers

AES offers the following series of temperature and humidity test chambers:

LH Series

Compact chambers ideal for small-scale, steady-state testing.

- Space-saving benchtop design

- Ideal for R&D or limited lab space

-

Precise environmental chamber humidity control without sacrificing performance

Temperature Range: -20°C to +94°C (-4°F to +201.2°F).

Humidity Range: 10% to 95% (98% with added options).

Available Volumes: 1.3, 5, and 10 cu ft.

BHD Series

Versatile, stackable chambers for everyday use and maximum efficiency.

- Mid-capacity design balances size and function

- Flexible for steady-state or cycling tests

- Reliable chamber temperature and humidity control

Temperature Range: -70°C to +180°C (-94°F to +356°F).

Humidity Range: 10% to 95% (98% with added options).

Available Volumes: 2 and 8 cu ft.

SCH Series

The most powerful humidity chamber available worldwide, engineered for scale.

- Durable construction for extended test cycles

- Expanded volumes for production-scale testing

- Optimized airflow and humidity stability

Temperature Range: -37°C to +180°C (-34.6°F to +356°F).

Humidity Range: 10% to 95% (98% with added options).

Available Volumes: 8 and 12 cu ft.

HD Series

Deliver fast change rates for high-performance testing and long-term reliability.

- Handles rigorous test protocols with ease

- Rugged design supports long-duration studies

- Custom options available for unique requirements

Temperature Range: -70°C to +180°C (-94°F to +356°F).

Humidity Range: 10% to 95% (98% with added options).

Available Volumes: 2, 8, 10, 13, 18, 27, 36, 48, 64, 80, 96 cu ft.

Industries That Rely on Humidity Chambers

A humidity-controlled chamber from AES simulates real-world moisture conditions so industries can validate product safety, performance, and durability. From sensitive components to large-scale systems, AES chambers are built to meet the unique challenges of each application.

Explore how humidity testing supports key industries:

- Electric Vehicles (EVs): Rigorous thermal stress testing to validate battery safety and performances.

- Packaging: Comprehensive testing to guarantee your packaging effectively protects your product during transit and storage

- Energy Storage: Evaluate cell and pack performance under varying environmental conditions.

- Paints & Coating: Ensue the quality and longevity of your products.

- Military & Defense: Meet strict military standards (MIL-STDs) with thermal testing.

Want to learn more about how we support each industry? Explore the industries we serve to see how our solutions align with your specific needs.

Reliable Temperature & Humidity Control Systems

AES chambers combine advanced heating, cooling, airflow, and humidity systems to deliver stable, repeatable conditions for critical testing.

- Heating system – Fast-response electric heaters deliver uniform temperatures up to 180 °C (356 °F) with precision of ±0.5°C.

- Cooling options – ES chambers consists of a self-contained mechanical refrigeration system with a single-stage or cascade configuration. Air- or water-cooled systems, with optional LN₂/CO₂ boost for rapid pulldown. Even without boost cooling, AES standard cascade refrigeration systems have the fastest standard change rates of any environmental test chamber manufacturer.

- Air circulation – Proprietary fan and baffle design ensure consistent chamber conditions.

- Humidity system – Vapor generator control supports 10–98% RH, with optional features to expand the range or prevent condensation.

AES chambers are engineered for accuracy, flexibility, and long-term reliability, so you can focus on results, not limitations.

Humidity System

AES uses vapor generator systems to give you precise control over the humidity conditions of your chambers’ internal workspaces. The vapor generator system is a closed stainless steel or copper tube. An element heats a constant water source creating vapor or steam that travels through the tube and mixes with conditioned air in a plenum before moving into the workspace. Notably, this water source must be treated and demineralized to avoid contaminating the test.

This system yields a standard relative humidity (RH) range between 10% and 98%.

Optional Features to Increase Humidity Range

High Humidity Sensors let you measure humidity as high as 98% RH.

Dry Air Purge Through Desiccant Air Dryers can achieve humidity as low as 5% RH. It compresses air through a desiccant system, absorbing the moisture before it moves into the workspace.

Dry Nitrogen Purges prevent condensation and frost from accumulating on DUT surfaces at colder temperatures by forcing out the moisture-heavy air. This also prevents the oxidation of metals at high temperatures.

Recirculating Desiccant Air Dryers are a more feasible option for larger chambers. Air is circulated through a desiccant system and then returned to the chamber, often cycled through a honeycomb wheel that releases captured moisture into the external workspace.

Associated Environmental Systems has developed a Dew Point Calculator to help you determine whether you'll need optional features for your humidity systems.

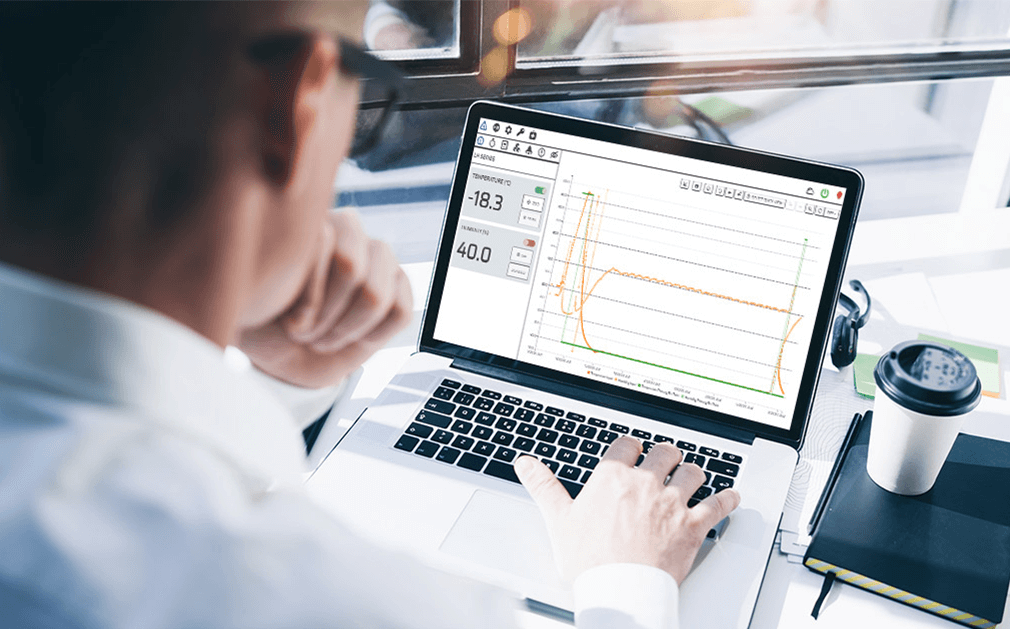

Remote Monitoring With AESONE CONNECT®

AESONE CONNECT® comes standard with every AES humidity chamber, giving you complete control from anywhere. Remotely monitor, adjust, and analyze tests through a secure web dashboard.

- View real-time and historical data

- Create, edit, and share test profiles remotely

- Control user access with robust authentication

- Retrofit available for most legacy chambers

Humidity Chamber Maintenance

Proper service protects your investment, ensures reliable results, and extends system lifespan for 10 years or more. Properly conditioned water protects the system, prevents corrosion, and ensures consistent results. AES suggests defined ranges for resistivity of (0.05MΩ * cm to 6MΩ * cm, conductivity, 20µS to 0.167µS TDS: 10 ppm to 1 ppm, and total dissolved solids (TDS) (10 ppm to 1 ppm). The demineralizing cartridges used to condition the water should be checked monthly.

In addition, be aware of any buildup of sediments and sitting water, which can lead to mold or mildew that corrodes metal over time. AES service technicians are available nationwide to support your equipment. Water quality checks, preventative care, and more, our team helps extend the lifespan of your chamber and keep it running reliably.

Humidity Chamber Resources & FAQS

What is a humidity chamber?

A humidity chamber is a controlled testing environment that regulates both temperature and moisture levels. It allows engineers to replicate real-world conditions and study how products respond to changes in heat and humidity.

How does a humidity chamber work?

Leading test chamber manufacturers build humidity chambers with closed vapor generator systems. They require properly conditioned water as well as regular maintenance to ensure performance. Read more on How Humidity Chambers Work.

How accurate is a humidity chamber?

Most modern humidity chambers hold precision of about ±0.5 °C for temperature and ±2–3% relative humidity. This level of testing accuracy ensures repeatable results for product validation, compliance, and long-term reliability studies.

What is the temperature range of a humidity chamber?

Standard humidity chambers operate from –37 °C to +180 °C (–34.6 °F to 356 °F), with extended models reaching as low as –70 °C (–94 °F). Within this range, chambers maintain stable conditions to support diverse testing requirements.

What are the main functions of a humidity chamber?

Humidity chambers rely on vapor generator systems to create specified conditions in the workspace. Companies across industries (from packaging to electronics, pharma, communications, and more) test their products in humidity to evaluate the effectiveness of those products in different environmental conditions and set expectations for consumers. Read more on Test Chamber Functions.

Humidity chambers: Calculating dew point to fit your testing

The relationship between temperature, relative humidity, and dew point can be a bit complicated to calculate, but it’s vital for ensuring reliable and consistent humidity testing. Read more on Calculating Dew Point.

More on Humidity Chambers:

Ready to get started?

Request a quote today by phone, chat, or form — see how AES delivers reliable chamber temperature, humidity, and environmental performance.

.png?width=326&height=252&name=SD-508%20(2).png)